.jpg.jpg)

How to Choose the Right Edge Banding Machine for Your Workshop

In modern woodworking and furniture production, precision and efficiency are everything. When you're producing cabinets, wardrobes, or office furniture, having clean, smooth, and durable edges is a sign of quality craftsmanship. That's why investing in the right edge banding machine is one of the smartest decisions a workshop can make.

However, with so many edge banders on the market—from manual to fully automatic systems—it can be overwhelming to decide which one fits your needs. This guide will help you understand how to choose the best edge banding machine for your woodworking workshop, covering everything from machine types and key features to budget, maintenance, and brand recommendations.

1. Understand Your Workshop's Production Needs

Before comparing machines, take a close look at what you actually need.

- Production Volume: If your workshop produces a small number of furniture pieces per week, a manual or semi-automatic edge banding machine may be sufficient. However, for high-volume furniture factories, a fully automatic edge bander will significantly boost productivity and consistency.

- Material Type: Identify what materials you usually work with—MDF, particle board, plywood, or solid wood panels—and what type of edge banding materials you use (PVC, ABS, veneer, or melamine).

- Available Space: Edge banding machines vary in size; make sure your workshop layout can accommodate the chosen model without affecting workflow.

- Budget & ROI: While the cheapest option may seem appealing, consider your long-term needs. A higher-end wood edge banding machine can save labor, improve precision, and reduce waste—offering a faster return on investment.

2. Types of Edge Banding Machines

Different workshops need different levels of automation. Let's compare the main types:

Manual Edge Banding Machines

Best for small woodworking shops or custom furniture makers. These machines require manual feeding and trimming, making them affordable but labor-intensive. They're ideal for low-output production and basic edge sealing.

Semi-Automatic Edge Banders

These machines combine manual feeding with automated gluing, pressing, and trimming. They provide a balance between cost and productivity—perfect for medium-scale manufacturers who produce a steady amount of panels daily.

Fully Automatic Edge Banding Machines

For large-scale, continuous production lines, a fully automatic edge banding machine is the gold standard. It integrates feeding, gluing, trimming, scraping, and buffing into one seamless process. The result is faster cycle times, consistent quality, and reduced operator intervention.

If your workshop is planning to scale, choosing an automatic edge bander ensures long-term efficiency and competitiveness.

3. Key Features to Look For

When comparing machines, evaluate the following technical aspects:

- Feed Speed: A faster feed rate (e.g., 15–25 m/min) increases production efficiency.

- Edge Thickness & Panel Size Range: Make sure the machine can handle the range of materials and dimensions you work with.

- Glue System: Look for precision temperature control and uniform glue application. Hot-melt EVA systems are standard, while PUR systems are ideal for moisture resistance and superior bonding.

- Trimming and Buffing Units: High-precision trimming tools and automatic buffing improve the finish, reducing the need for manual polishing.

- Digital Controls & Touch Screens: Modern edge banders feature user-friendly control panels that simplify setup and adjustment.

- Dust Extraction & Cleanliness: Efficient chip removal keeps the workspace clean and prevents damage to the panels or internal components.

Pro Tip: Always choose an edge banding machine that matches your most frequent material and edge types rather than occasional projects.

4. Material Compatibility and Edge Quality

The edge finish defines your furniture's quality. Different edge materials require specific temperature and pressure settings.

- PVC and ABS edge banding: Common for commercial furniture and cabinets, offering durability and color consistency.

- Wood veneer edge banding: Ideal for premium furniture with natural finishes but requires gentle handling and precise temperature control.

- Melamine edge banding: Cost-effective, suitable for decorative surfaces and flat panels.

Your machine should provide consistent bonding pressure, precise trimming, and smooth surface finishing to ensure professional-grade results every time.

5. Maintenance and Durability

Choosing a reliable machine is only the first step—keeping it in top condition ensures consistent output and longer service life.

- Regular Cleaning: Glue pots, rollers, and trimming tools must be cleaned regularly to avoid clogging or uneven glue lines.

- Lubrication: Keep moving components well-oiled to prevent wear and tear.

- Calibration Checks: Periodic adjustment of feed rollers and cutters guarantees smooth, accurate edge finishing.

- Replace Worn Parts Promptly: Use original or high-quality spare parts to maintain precision.

A well-maintained edge banding machine can easily run efficiently for 10 years or more.

6. After-Sales Support and Spare Parts

When selecting a supplier, technical support matters as much as the machine itself. Ensure your supplier provides:

- Quick response for maintenance requests

- Availability of replacement parts and consumables

- Remote troubleshooting and training services

- Clear warranty and service terms

This support can dramatically reduce downtime and keep your workshop running smoothly.

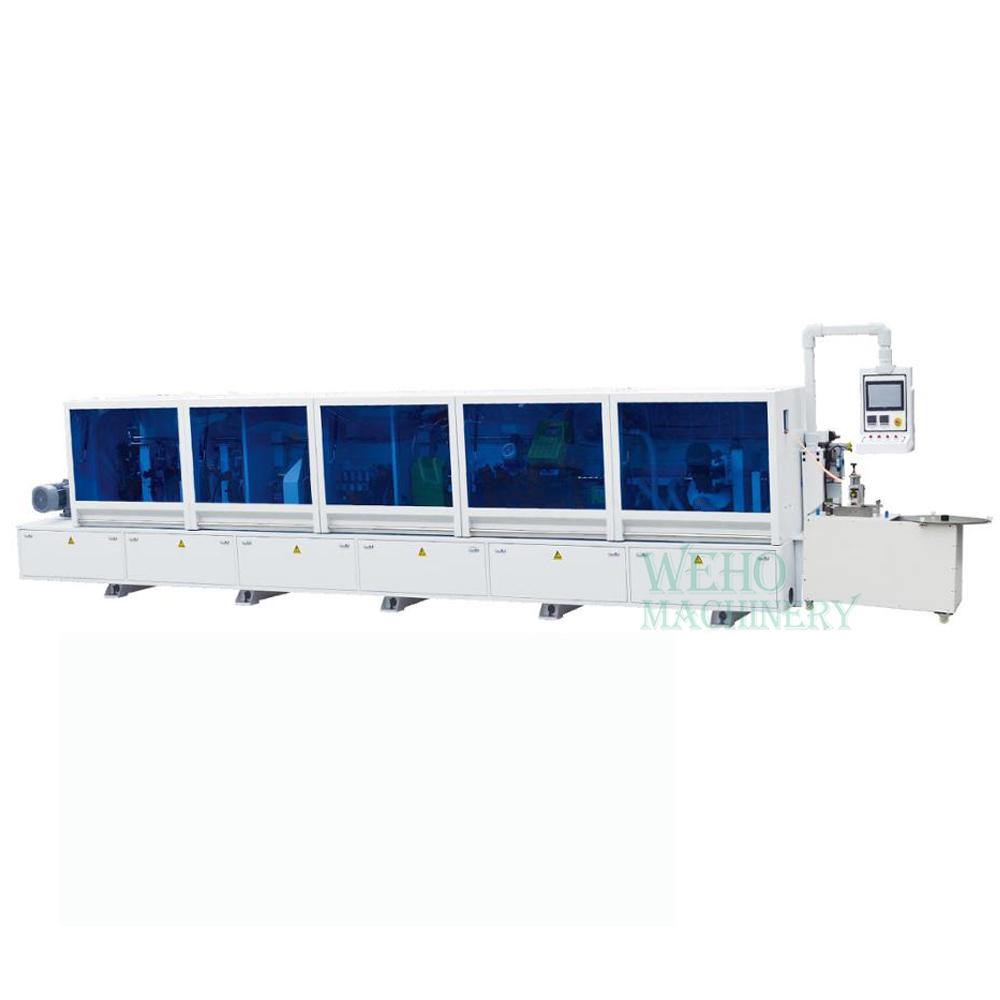

7. Why Choose WEHO Edge Banding Machines

If you’re looking for a reliable, high-performance edge banding machine, WEHO is a name trusted by professionals worldwide.

WEHO specializes in advanced woodworking machinery designed for precision, durability, and productivity. Our automatic edge banders feature intelligent temperature control, efficient glue systems, and integrated trimming and buffing units. Whether you operate a small furniture shop or a large-scale factory, WEHO offers models that meet your exact requirements.

What sets WEHO apart:

- Comprehensive customization: Machines tailored for PVC, ABS, or veneer edge materials.

- User-friendly design: Intuitive touch screens and automation that simplify operation.

- Quality assurance: Built with high-grade components for long-lasting reliability.

- Dedicated after-sales service: Global technical support and fast parts delivery.

With WEHO edge banding machines, you can improve your product quality, shorten delivery times, and enhance your production efficiency—all while keeping operational costs low.

8. Final Tips for Making the Right Decision

Before you finalize your purchase:

- Assess your daily production volume and material range.

- Compare features and automation levels that fit your workflow.

- Ask for machine demos or sample runs to test performance.

- Consider long-term ROI, not just initial cost.

- Choose a trusted brand—like WEHO—that provides ongoing technical support and proven reliability.

Investing wisely in the right edge banding equipment will pay off in smoother workflows, higher-quality furniture, and better profits.

Conclusion

Selecting the right edge banding machine for your workshop isn't just about buying a piece of equipment—it's about building a foundation for efficiency and craftsmanship. By evaluating your production needs, understanding machine types, and focusing on long-term reliability, you can ensure your investment delivers exceptional value.

Whether you need a manual, semi-automatic, or fully automatic edge bander, WEHO offers the perfect solution to elevate your woodworking business. With advanced technology and trusted quality, WEHO helps workshops around the world achieve cleaner edges, faster production, and superior results.