How to Choose The Right Saw Blade Sharpener Machine

Choosing the right saw blade sharpener is crucial for maintaining blade sharpness, improving cutting performance, and reducing costs in your workshop or factory. Whether you operate a small woodworking shop or a large industrial cutting production line, the right machine can significantly improve productivity and extend saw blade life. Therefore, selecting the right saw blade sharpener is an important step. The following article will help you choose the right saw blade sharpener.

What Is a Saw Blade Sharpener Machine?

A saw blade sharpener is a specialized device designed to restore the cutting edge of worn or dulled saw blades through precise grinding and polishing processes. It is suitable for various types of saw blades, including circular saw blades, band saw blades, and carbide (TCT) saw blades, and is widely used in woodworking, metal cutting, and industrial manufacturing. By ensuring consistency in tooth profile and sharpness, saw blade sharpeners help improve cutting efficiency and accuracy, extend saw blade life, and significantly reduce tooling and operating costs.

Types of Saw Blade Sharpener Machines

Understanding the different types of knife sharpeners is a crucial step in choosing the right one for your needs.

Manual Saw Blade Sharpener Machine

For workshops with low to moderate grinding needs, manual saw blade sharpeners are a practical and affordable solution. Relying on manual adjustment and operator setting of the grinding angle and tooth position, they are suitable for circular saw blades and basic band saw blades. Simple to operate, they are best suited for occasional sharpening in small repair shops and woodworking workshops, with lower initial costs, but not suitable for high-volume or high-precision applications. For users seeking a stable, simple, and reliable saw blade sharpener, a manual sharpener remains a good choice.

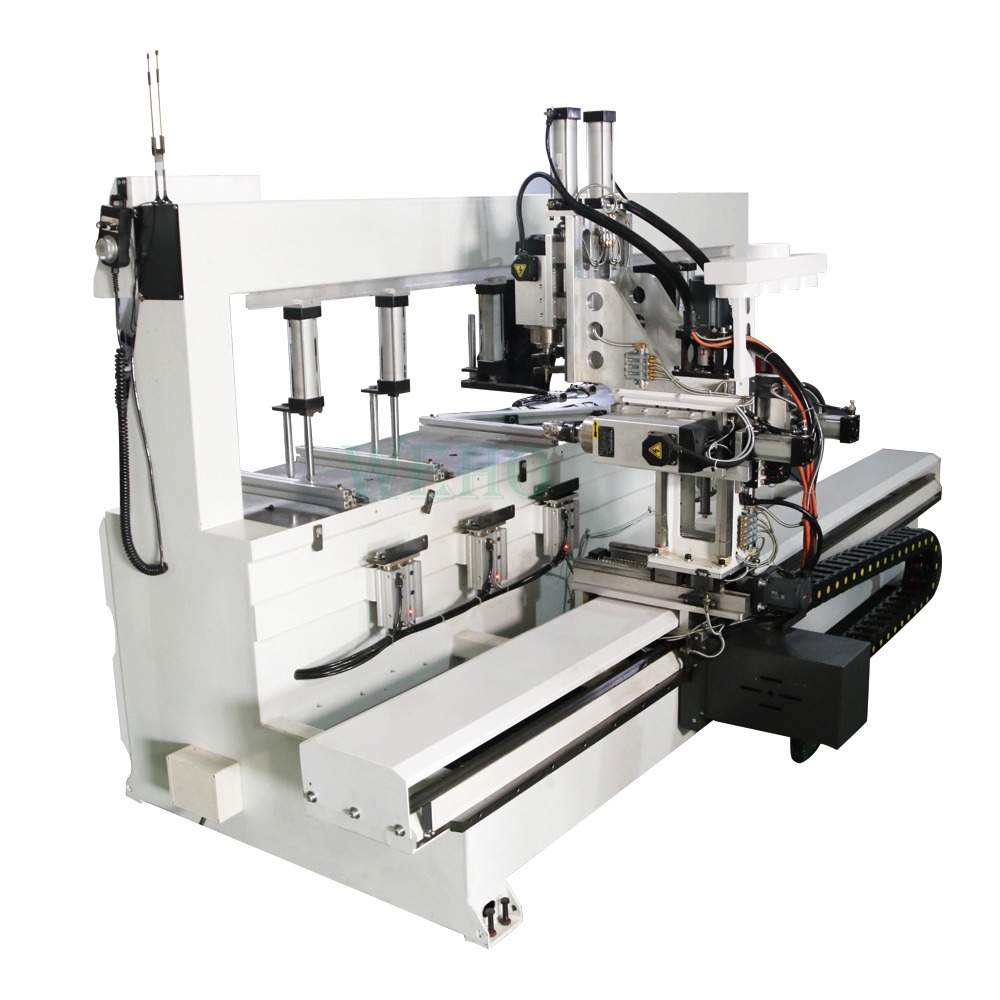

automatic band saw blade sharpening machine

For higher efficiency and more consistent sharpening results, automatic sharpening machines are the best choice. These machines are designed to minimize human intervention, thus efficiently processing blades. They are specifically designed for high efficiency, high precision, and consistent grinding quality in industrial environments. Therefore, automatic band saw blade grinding machines are particularly important in metal processing and high-volume production environments. They automate saw blade feeding, angle measurement, tooth positioning, and grinding, ensuring consistent grinding results and saving labor costs, although they are more expensive than manual grinding machines. Their faster processing speed, higher density, and better repeatability make them the preferred solution for factories seeking to improve productivity and achieve long-term cost savings.

Working Principle of a Saw Blade Sharpener Machine

The working principle of a saw blade sharpening machine is to restore the cutting edge of a worn saw blade using controlled grinding and precise positioning. First, the saw blade is securely mounted on the machine's clamps to ensure stability and alignment during the grinding process. Then, the operator sets key parameters such as tooth angle, grinding depth, and tooth pitch according to the type of saw blade and the application scenario. After the machine starts, the grinding wheel moves towards the saw teeth, removing a small, controllable amount of material from each tooth, thus reshaping the cutting edge. In manual saw blade grinding machines, this process is operator-guided, with each tooth positioned individually. In contrast, automatic grinding machine saw blade systems use mechanical or electronic positioning to ensure consistent positioning of each tooth. For high-efficiency models, such as automatic band saw blade grinding machines, the entire process is fully automated, ensuring uniform grinding quality, reducing human error, and guaranteeing stable performance for large-volume saw blade grinding.

The process is as follows:

Blade Mounting & Alignment → Parameter Setting → Grinding / Sharpening → Indexing / Repeat → Finished Sharpened Blade → Inspection & Output

Applications of Saw Blade Sharpener Machines

Saw blade sharpening machines are widely used in industries with extremely high requirements for cutting precision, efficiency, and tool life. Different industries use these machines for different purposes, but all aim to maintain stable cutting performance and reduce operating costs.

Woodworking Industry

In woodworking shops and furniture manufacturing plants, saw blade grinders are mainly used for grinding circular saw blades and carbide saw blades. Their primary function is to ensure clean and precise cutting of planks, solid wood, and composite materials, ensuring smooth cut surfaces and dimensional stability. Regular grinding ensures smooth cutting, reduces material waste, extends saw blade life, improves production efficiency, and lowers saw blade replacement costs. Commonly used models include circular saw blade sharpening machine, manual or semi-automatic saw blade sharpening machine, and TCT alloy saw blade sharpening machine.

Metal Processing Industry

In metal cutting workshops and steel service centers, the most commonly used equipment is the automatic band saw blade sharpening machine. These machines are used to restore the tooth profile of band saw blades ground onto steel, aluminum, and other metals. Their main advantages are maintaining cutting stability, preventing blade deviation and breakage, and ensuring consistent performance throughout continuous production. Common models include automatic band saw blade sharpening machine and fully automatic saw blade sharpening machine.

Manufacturing & Industrial Production

In large-scale manufacturing environments, saw blade sharpening machines are widely used in typical production settings to assist with the routine maintenance of cutting tools. These machines help production lines avoid downtime due to dull saw blades, maintain consistent cutting accuracy, and reduce the cost of frequent saw blade replacements. Depending on production scale, manual or automatic saw blade sharpening machines can be selected. Common models include automatic saw blade sharpening machines and CNC saw blade sharpening machines.

Construction & Building Materials Industry

In the construction and profile processing industry, saw blade sharpeners are used to maintain saw blades used for cutting wood, aluminum profiles, plastics, and light metals. Proper sharpening can improve cutting speed and safety on the construction site, and also helps reduce tool wear costs and improve processing accuracy. Therefore, it is an essential piece of equipment in many areas of the construction industry. Common models include circular saw blade sharpeners and semi-automatic or automatic saw blade sharpeners.

Tool Maintenance & Service Centers

Tool repair shops and blade repair centers rely on saw blade sharpeners to refurbish customers' saw blades. This ensures consistent sharpening quality across different saw blades while guaranteeing fast turnaround times to meet diverse customer needs. Automatic band saw blade sharpeners are particularly important for efficiently handling large volumes of orders. Common models include multi-functional saw blade sharpeners, adjustable angle saw blade sharpeners, customizable clamping saw blade sharpeners, and automatic or semi-automatic saw blade sharpeners.

Key Factors to Consider When Choosing a Saw Blade Sharpener Machine

Choosing the right saw blade sharpening machine requires considering not only price, but also whether the machine matches your saw blade type, production needs, and long-term operating costs.

Blade Type & Application Compatibility

Different saw blades require different grinding methods. Before selecting a machine, you need to confirm whether the machine can support your saw blade; confirm whether it is a circular saw blade or a band saw blade, and whether it uses TCT blades or standard steel blades; confirm its tooth pitch, diameter, and tooth profile to ensure that the machine matches your needs.

degree of automation

Manual saw blade sharpening machines are suitable for small-batch or flexible sharpening needs, while automatic saw blade sharpening machines offer consistent quality, higher output, and reduced labor costs. The level of automation directly impacts efficiency and labor costs. Deciding between manual and automatic operation is one of the key factors determining cost.

Grinding precision and consistency

Grinding precision is crucial to blade performance. A good saw blade sharpener should maintain consistent tooth angles, ensure uniform grinding depth, and provide repeatable grinding results. Higher precision can lead to smoother cuts, less vibration, and longer blade life.

Production capacity and efficiency

Before purchasing a machine, you need to consider your production needs, such as how many blades you need to grind. For users with large production volumes, prioritize machines that can quickly index speeds and support continuous or automated operation. This is especially important when choosing a saw blade grinder for industrial use.

Ease of operation and setup

When choosing a machine, consider its ease of adjustment, operation, and maintenance. Simple operation, clear parameter settings, and quick saw blade clamping function can significantly reduce training time and operational errors.

Customization and flexibility

For industries that require non-standard sized blades and tooth profiles, machines equipped with adjustable clamps or custom grinding solutions offer greater long-term flexibility, especially suitable for service centers or multi-industry users.

After-sales service

Reliable technology is crucial. When selecting a supplier, you need to consider the supplier's spare parts availability, technical training, and whether there is remote or on-site service support. A trustworthy manufacturer with good after-sales service can ensure the machine operates stably throughout its entire life cycle.

Cost

Before purchasing a machine, in addition to considering the purchase cost, it is also necessary to consider the subsequent maintenance costs, energy costs, and labor savings. Although the initial investment cost is high, a high-quality automatic saw blade sharpening machine can usually bring greater long-term value to a business.

WEHO is the best choice

WEHO has a long-standing focus on tool grinding and industrial machinery, possessing deep understanding of the practical production challenges across various industries, including woodworking, metal cutting, and manufacturing. Leveraging its extensive practical experience, WEHO designs practical, stable, and durable machines. It offers a full range of saw blade sharpeners, including manual sharpeners for workshops, automated systems for factories, and automatic band saw blade sharpeners for high-volume metal cutting. Whether for small-scale equipment or industrial-grade solutions, WEHO can accurately provide the right machine.

Despite the varying needs of each factory, WEHO offers customized solutions based on blade type, size, tooth profile, and production requirements. From specialized fixtures to adjustable sharpening angles and automation options, WEHO's machines are designed to meet your machine's needs, not make you adapt to the machine.

WEHO offers long-term after-sales service with a professional team providing expert support, including installation guidance, operator training, technical documentation, and rapid troubleshooting. Ample spare parts supply and continuous technical support ensure stable machine performance throughout its entire lifespan.

WEHO is more than just a manufacturer or supplier; it's a partner dedicated to helping customers gradually improve cutting efficiency, reduce saw blade costs, and increase production productivity. This solution-oriented philosophy is what has led many users to start with WEHO and continue to collaborate with them throughout their business development.

FAQS

Q1: Which industries are suitable for automatic knife sharpening machines?

A1: Automatic knife sharpening machines are best suited for industries with high production volume, strict quality requirements, and long operating hours. Industries such as woodworking and furniture manufacturing, metal processing and steel service centers, and the construction industry can provide stable sharpening precision, reduce labor costs, and extend tool life, making it a key investment for companies that value efficiency and long-term cost control.

Q2: How often should saw blades be sharpened?

A2: The frequency of saw blade sharpening depends on the usage frequency, the material being cut, and the type of saw blade; there is no fixed schedule. High-frequency industrial applications generally require sharpening every few days to 1-2 weeks; medium-frequency workshops require sharpening every few weeks or 1-2 months; low-frequency or occasional use may only require sharpening as long as the cutting quality remains consistent.

Q3: Does WEHO support customized saw blade sharpening solutions?

A3: Yes, WEHO fully supports customized saw blade sharpening solutions, WEHO doesn’t just sell standard grinding machines — we tailor solutions to your blade type, application, production volume, and workflow requirements. This means your machine is built to match your exact use case rather than forcing you to adapt your process to the machine.

Q4: Is there after-sales service after purchase? Is technical support provided?

A4: Yes, WEHO Machinery provides comprehensive after-sales service and technical support after purchase, and this is a core part of our commitment to customer success. WEHO provides full after-sales service and technical support, including installation, training, troubleshooting help, spare parts supply, and ongoing optimization assistance to ensure long-term stable operation after your purchase.

Q5: What types of saw blades can a WEHO saw blade sharpener process?

A5: WEHO saw blade sharpener machines are designed to handle a wide range of blade types used across woodworking, metal cutting, and general manufacturing — making them versatile solutions for workshops and industrial production lines alike. WEHO saw blade sharpener machines can process circular saw blades, band saw blades, carbide-tipped (TCT) blades, and specialty/custom profile saw blades across woodworking, metalworking, and industrial manufacturing.