The necessary safety protection tools for woodworking circular saws

There may be two main causes of accidental injury and death caused by operating a circular saw. One is that the operator accidentally touched the saw blade of the circular saw; the other is that knots and defects appeared in the wood processing. Moisture or saw blade wear becomes dull, causing the wood to kick or eject violently. To this end, the circular sawing machine has adopted the following main measures:

1. Protective cover

The protective cover of the circular saw machine is divided into two types: the work surface and the work surface. The portable countertop protective cover is composed of a support frame, a plexiglass cover, a separating knife, and a brake pad. When working, the cover can swing on the support frame to adapt to the change of wood thickness. Reinforcing ribs are arranged in the cover to increase the anti-vibration ability of the cover. The woodworker can clearly see the sawing of the wood through the plexiglass cover. The protection device is suitable for boards that require high cutting precision, such as laminates, woodwork products, etc. The function of the protective cover under the workbench is to prevent the woodworker from being injured by the saw blade when cleaning the sawdust.

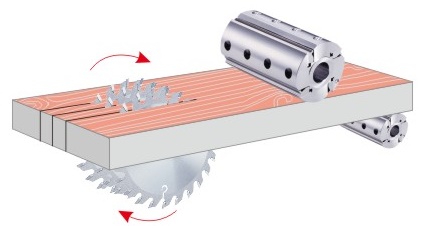

2. Anti-rebound device

In order to prevent wood rebound, circular sawing machines are generally equipped with a tail knife, a separating knife and a brake claw. The separating knife is a curved sickle blade with a smooth blade. It is usually made of wear-resistant steel, and its thickness is generally about 10% thicker than the saw blade. It should be noted that the separating knife should be firmly installed behind the saw blade to keep it on the same plane as the saw blade. After the saw blade is reground, the diameter of the saw blade will become smaller. At this time, the separation force should be adjusted. position. In addition, install brake pads (claws) before the circular saw enters the wood or on both sides of the protective cover. This is also an anti-rebound device. When wood is fed for processing, lift the brake pads (claws), and the wood can pass smoothly. If the wood vibrates and strikes back, the tip of the brake pad will jam the wood. Since the brake is often hit back strongly, it and the support shaft should be made of materials with sufficient impact strength.

3. Push rod, push block

There are many types of push rods and push blocks. Generally, it is designed and manufactured according to the needs of processing parts and procedures, and there is no uniform design standard. The commonly used push block is called the push wooden anvil, which can effectively protect the carpenter's thumb.

4. Safety fixture

When cutting a circular saw, you can use a wooden auxiliary ruler with a fixed-length stop. The stopper prevents human hands from entering the hazardous area.