| specification & Type | DC808 | |

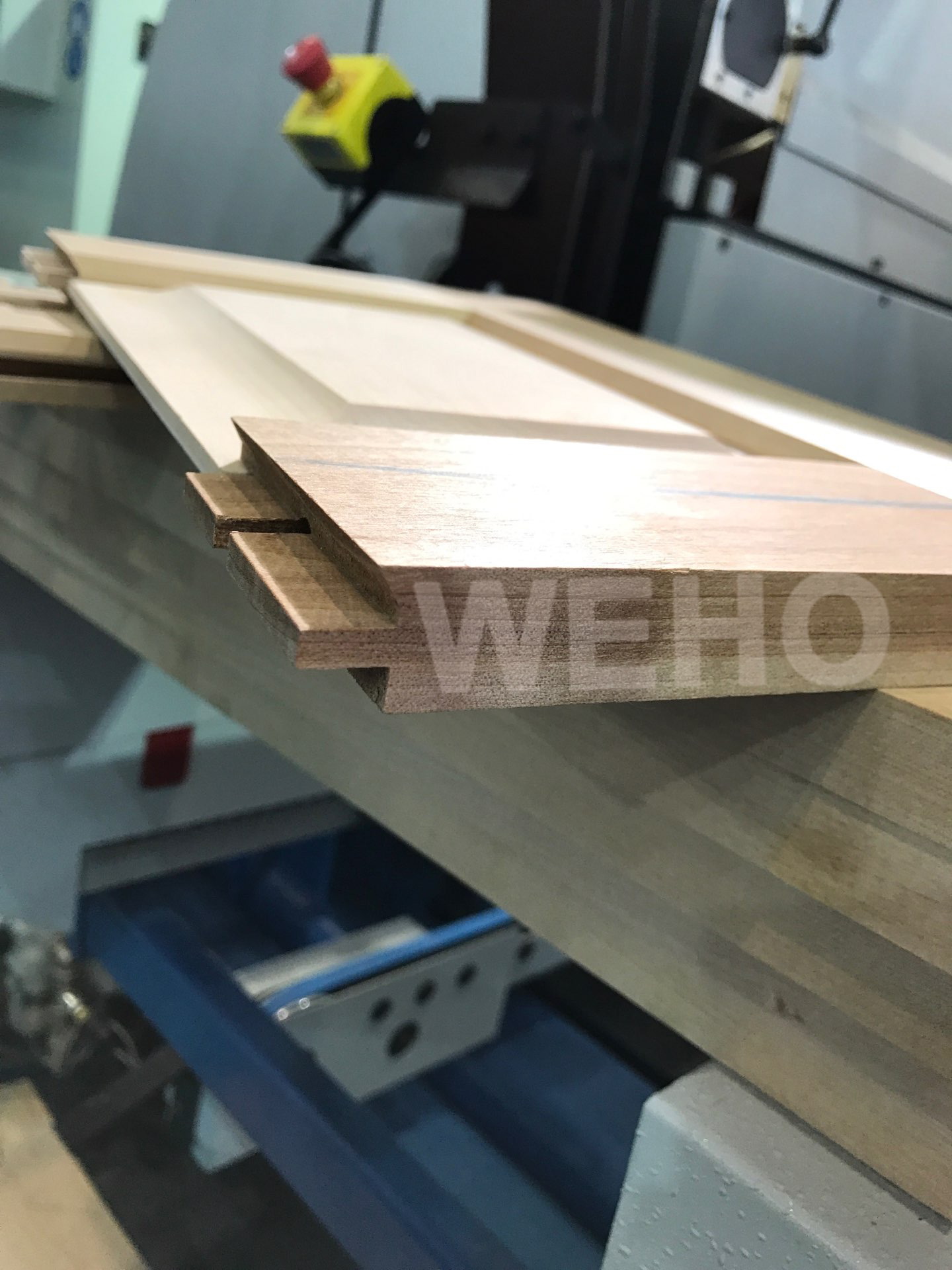

| Working width | 250mm | |

| 2500mm | ||

| Working thickness | 6mm | |

| 120mm | ||

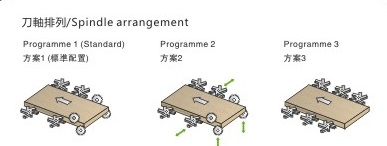

| Cutting out diameter (min-max) | Left saw unit | Φ125-Φ200 |

| Right saw unit | Φ125-Φ200 | |

| Left cut~off saw | Φ250-Φ300 | |

| Right cut—offsaw | Φ250-Φ300 | |

| First Left and right unit | Φ140-Φ160 | |

| Second Left and rihgt unit | Φ140-Φ160 | |

| Spindle diameter | Left saw unit | Φ25.4 |

| Right saw unit | Φ25.4 | |

| Left cut~off saw | Φ30 | |

| Right cut—offsaw | Φ30 | |

| First Left and right unit | Φ40 | |

| Second Left and rihgt unit | Φ40 | |

| Cutterhead length | 100 | |

| 175 | ||

| Motor power | Left scoring saw unit | 2.2KW 3KW/4HP/3HP |

| Right scoring saw unit | 2.2KW 3KW/4HP/3HP | |

| Left cut~off saw | 4KW 11KW/15HP | |

| Right cut—offsaw | 4KW 11KW/15HP | |

| First Left&right milling cutter | 2x5.5KW/7.5HP | |

| Second Left&right milling cutter | 2x7.5KW/10HP | |

| Feeding (Servo system) | 4.4KW | |

| Left & right milling cutter drive(Servo) | 4x1KW/1.3HP | |

| Pressure belt lift(Servo) | 2x1KW/1.3HP | |

| adjust Width(Servo) | 1KW/1.3HP | |

| Total motor power | 58.46KW-80.09hp | |

| Feed speed (m/min) | ||

| milling cutter Spindle speed(r/min | 7500 | |

| Dust pipe diameter(mm | Φ120 | |

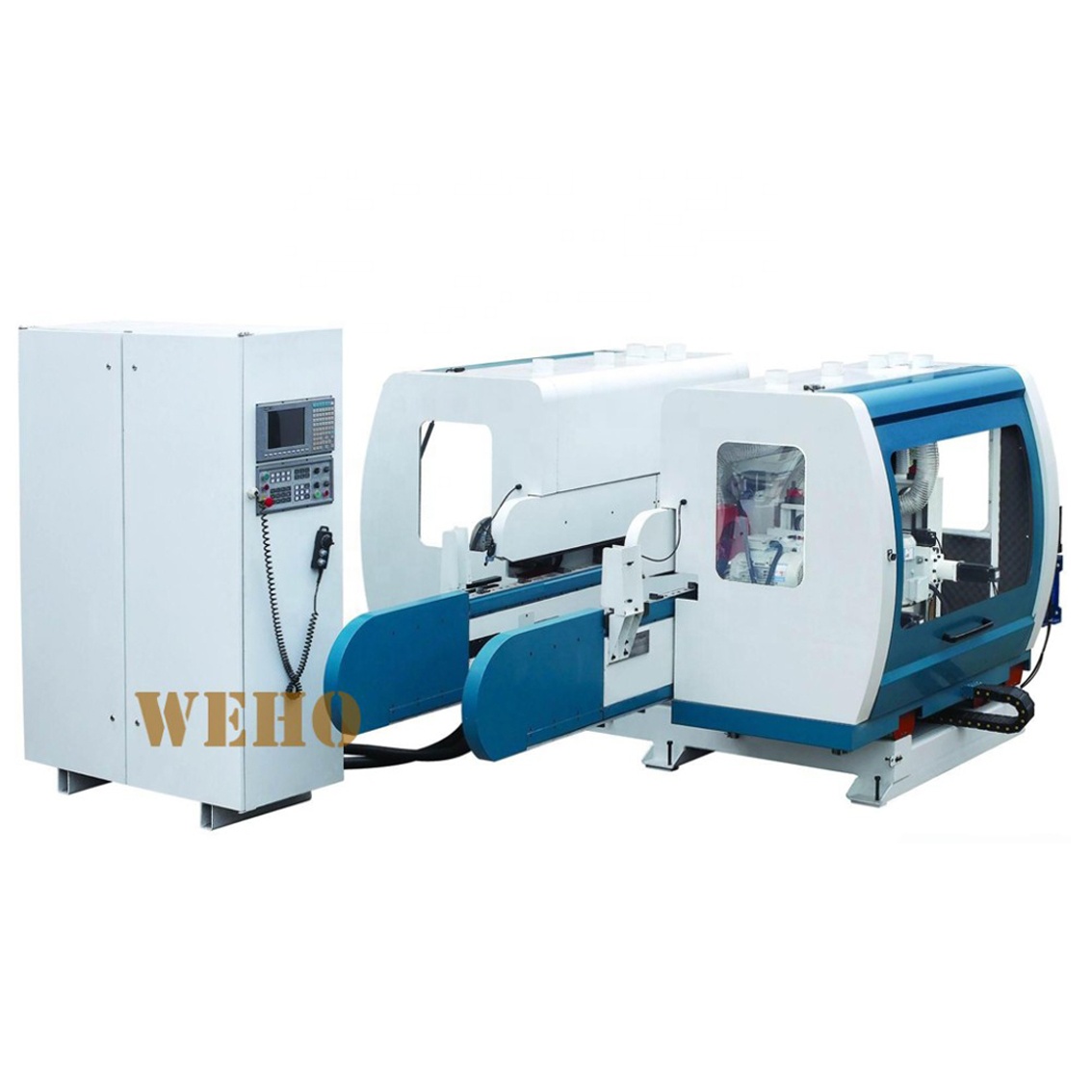

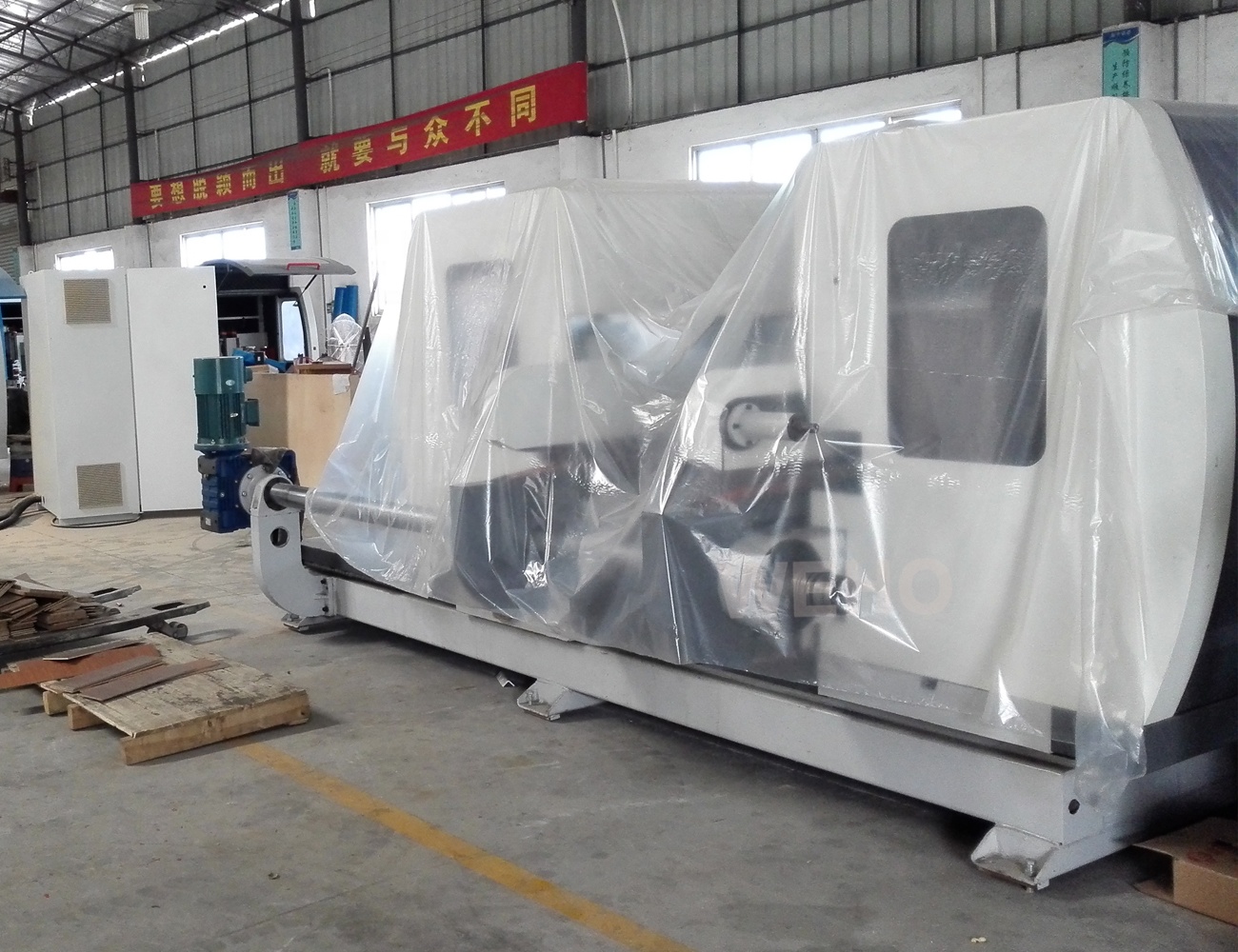

| Overaj_l machine dimensions (mm) (LxWxH) | 5300x4000x1950 | |

| Weight(tons approx) T | 5.8 | |