- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

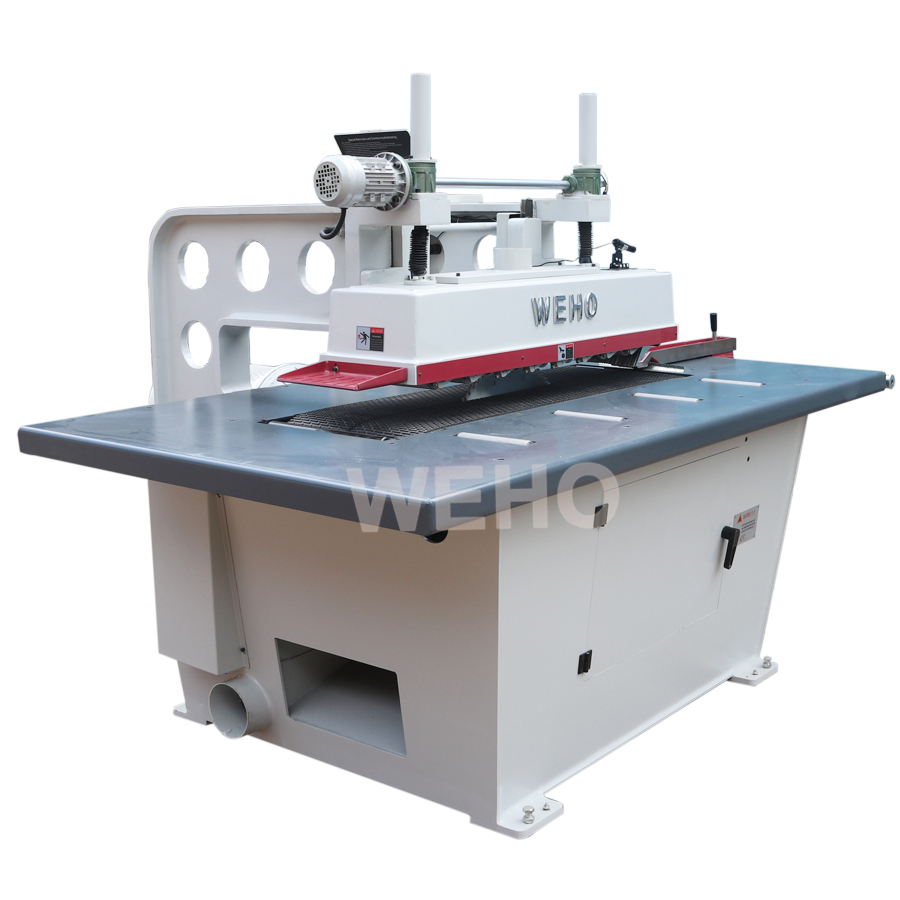

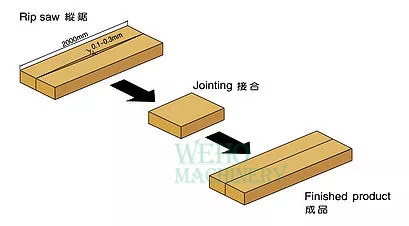

Industrial 3 phase rip saw straight line edge for cutting wood rip cut saw woodworking machine

Working thickness scope: 10-120mm

Max working width: 520mm

Min working length: 200mm

Deep throat: 520mm

Spindle speed: 3000r/min

Feeding speed: 10-26m/min

Spindle diameter: 50.8mm

Blade size: 455x5x50.8x70

Total power: 17.57kw

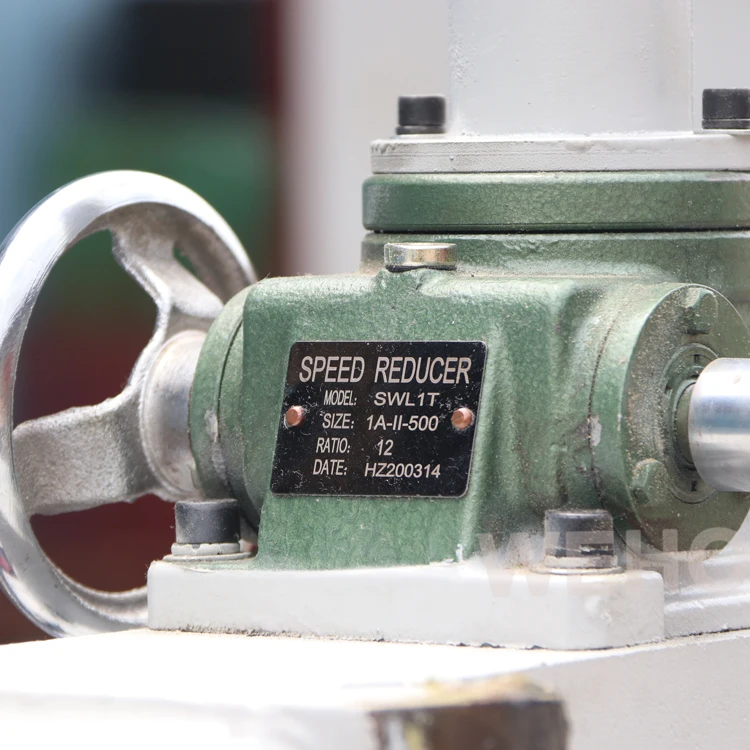

Rip saw machine Frame is made of quality steel welded with special technology. Through special process and precision finishing, superior reliability and precision are achieved.Reciprocating Saw carriage moved with gear motor, same to cnc beam saw structure, moves steady for perfect cutting. Time cleaning and lubrication for the chain plates. The spindle of rip saw machine assembly adopts special material through super finishing, precision assembling and dynamically balancing, guaranteeing superior stability and precision.

| Model | MJ165 |

| Working thickness scope | 10-120mm |

| Max working width | 520mm |

| Min working length | 200mm |

| Deep throat | 520mm |

| Spindle speed | 3000r/min |

| Feeding speed | 10-26m/min |

| Spindle diameter | 50.8mm |

| Blade size | 455x5x50.8x70 |

| Total power | 17.57kw |

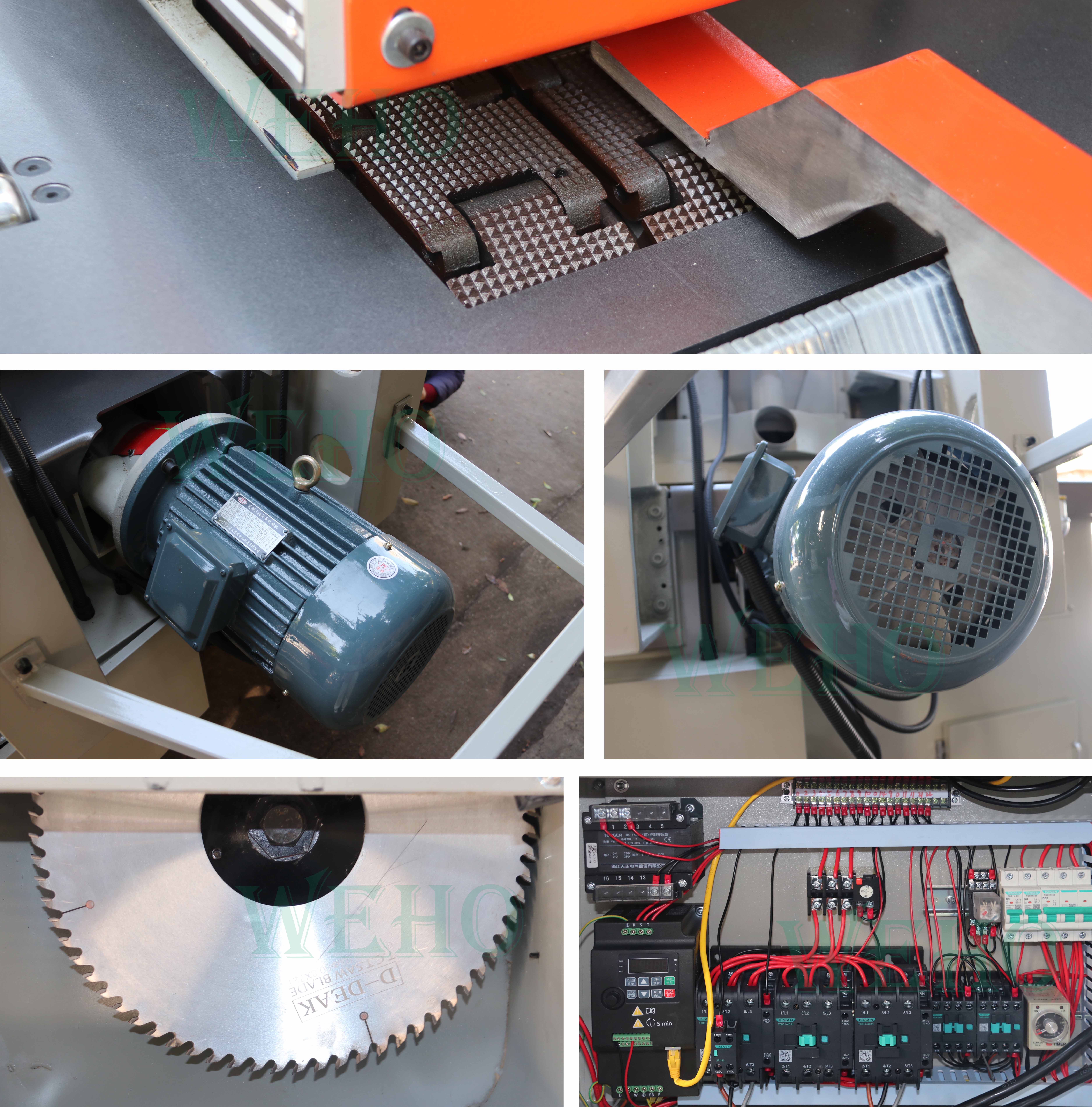

| Spindle motor power | 15kw |

| Feeding motor | 2.2kw |

| Lifting motor | 370W |

| Table size | 1870x1080mm |

| Table thickness | 6mm |

| Ruler length | 480mm |

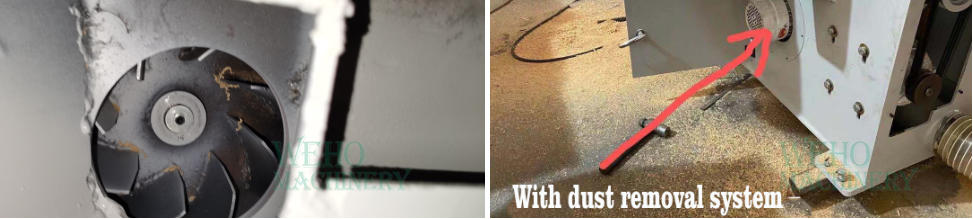

| Suction port diameter | 150-100mm |

| Overall dimension | 1900x1750x1500mm |

| Packing size | 2000x1600x1700mm |

| Machine weight | 1500kg |

Standard laser positioning device, reducing waste of woods for the straight line rip saw machine.

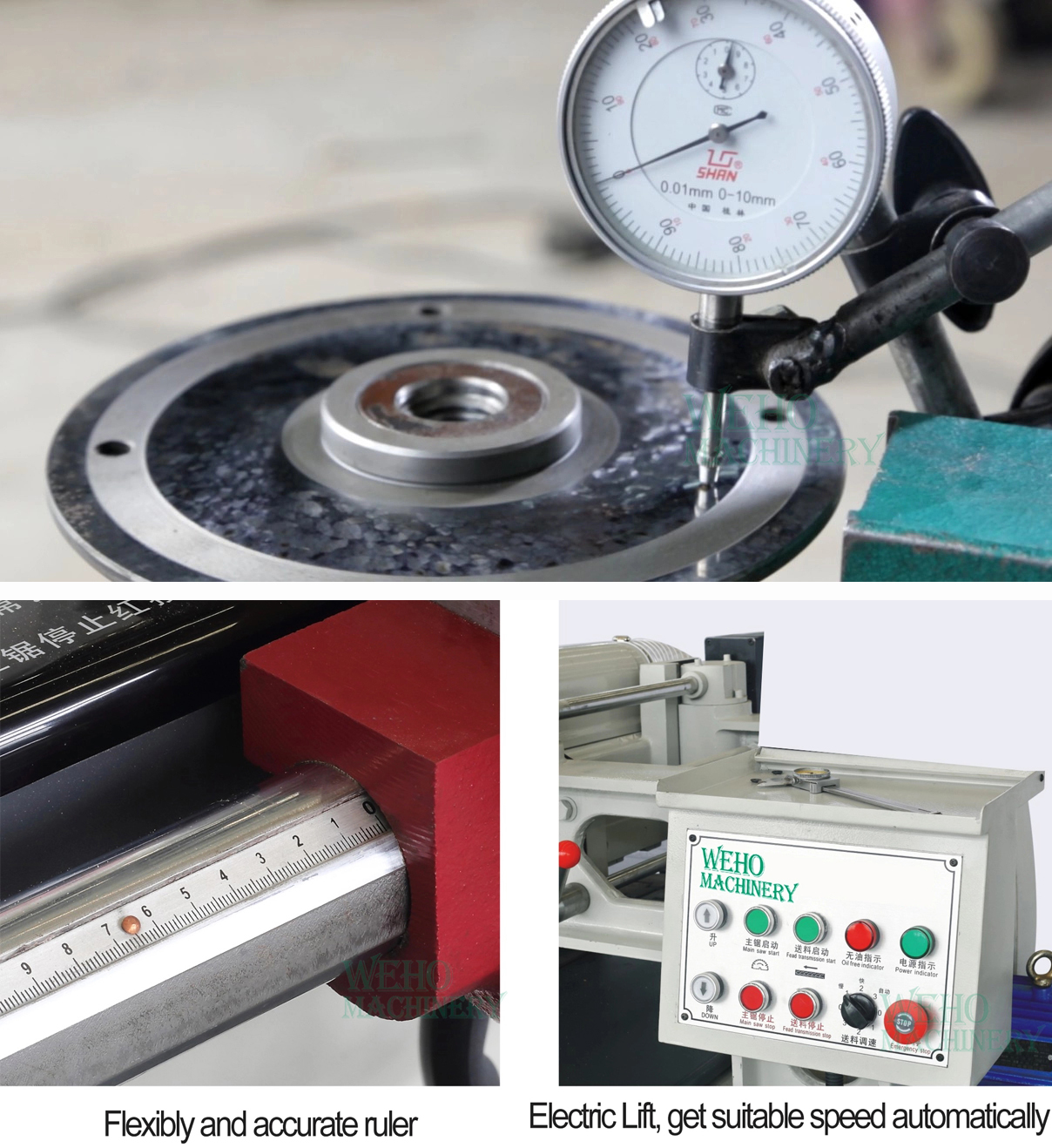

The fuselage table is lengthened; the thickness of the table is 15mm high-quality steel plate, which is lengthened by the ruler.

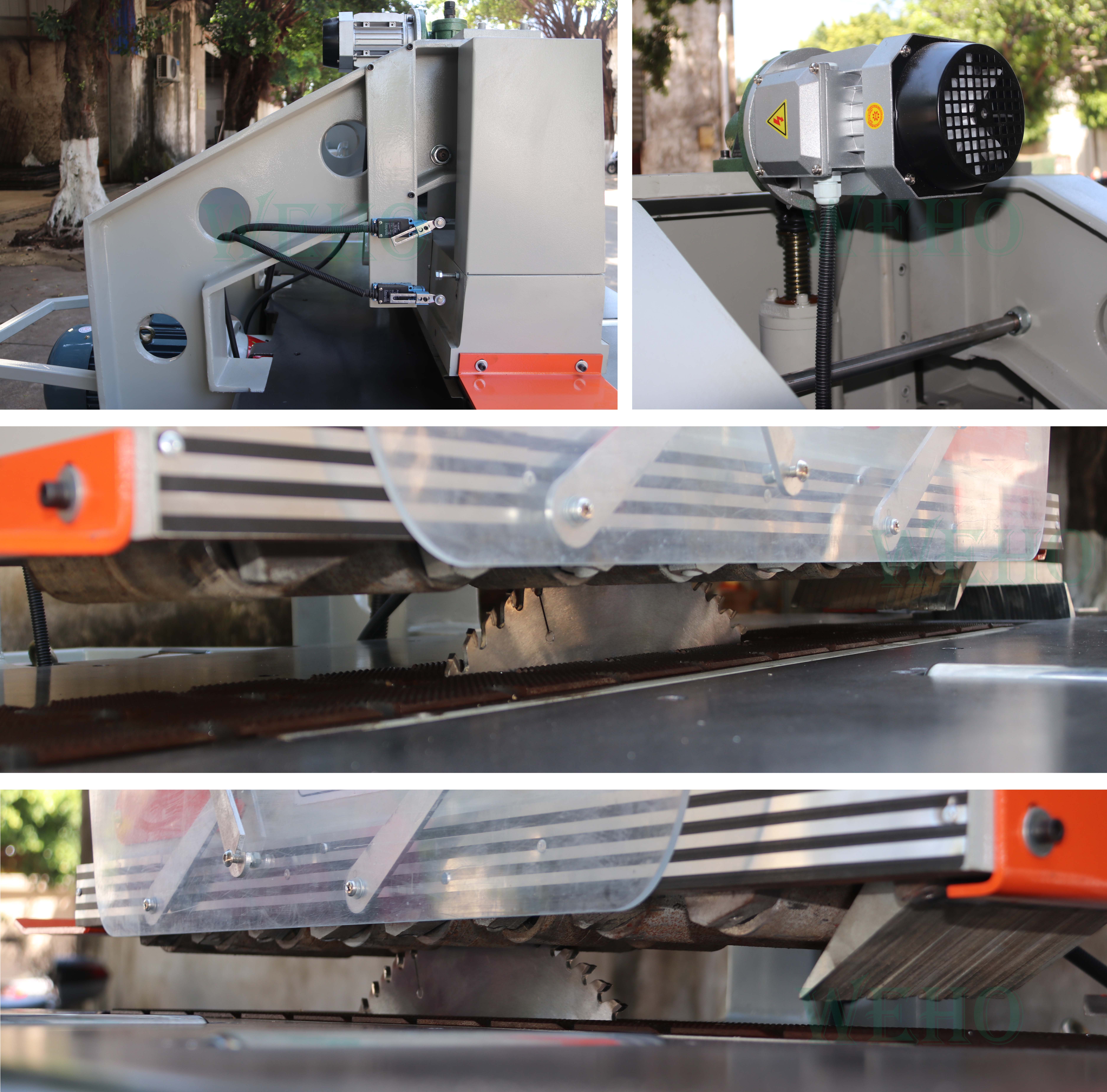

Chain plates and the guide rail of rip saw adopt special material and treatment, with precision finishing, providing superior surface hardness, precision and wear-resistance. Super service life.

The track shifting mechanism adopts high-precision stepless speed change; it is highly user-friendly in circuit design.

When the machine tool is not in use, the track automatically stops running, and the loading automatically resumes operation, which extends the life of the chain.

The main shaft is made of high-hardness tool steel material through 8 steps of precision machining.

What is even more remarkable is that the oil pump is used to supply oil to the main shaft and then supply oil to the chain.

All major electrical components and transmission bearings are made of international brand components with stable performance.

Configure triple upper and lower anti-bounce devices to ensure safer operation.

This reduces the operating temperature of the main shaft and prolongs the life of the main shaft.

Emphasis is placed on the interchangeability of the complete set of spindles, which will bring better convenience to future maintenance and replacement.

Main Features

1.The fuselage table is lengthened; the thickness of the table is 15mm high-quality steel plate, which is lengthened by the ruler.

2. The track shifting mechanism adopts high-precision stepless speed change; it is highly user-friendly in circuit design. When the machine tool is not in use, the track automatically stops running, and the loading automatically resumes operation, which extends the life of the chain.

3. The main shaft is made of high-hardness tool steel material through 8 steps of precision machining. What is even more remarkable is that the oil pump is used to supply oil to the main shaft and then supply oil to the chain. This reduces the operating temperature of the main shaft and prolongs the life of the main shaft. Emphasis is placed on the interchangeability of the complete set of spindles, which will bring better convenience to future maintenance and replacement.

4. Configure triple upper and lower anti-bounce devices to ensure safer operation

5. All major electrical components and transmission bearings are made of international brand components with stable performance

This reduces the operating temperature of the main shaft and prolongs the life of the main shaft.

Emphasis is placed on the interchangeability of the complete set of spindles, which will bring better convenience to future maintenance and replacement.

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions

2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 008613378477841. After buying, technical supporting contact 008613326792205

3 Phase Rip Saw

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.