- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- weho@wehomachinery.com

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

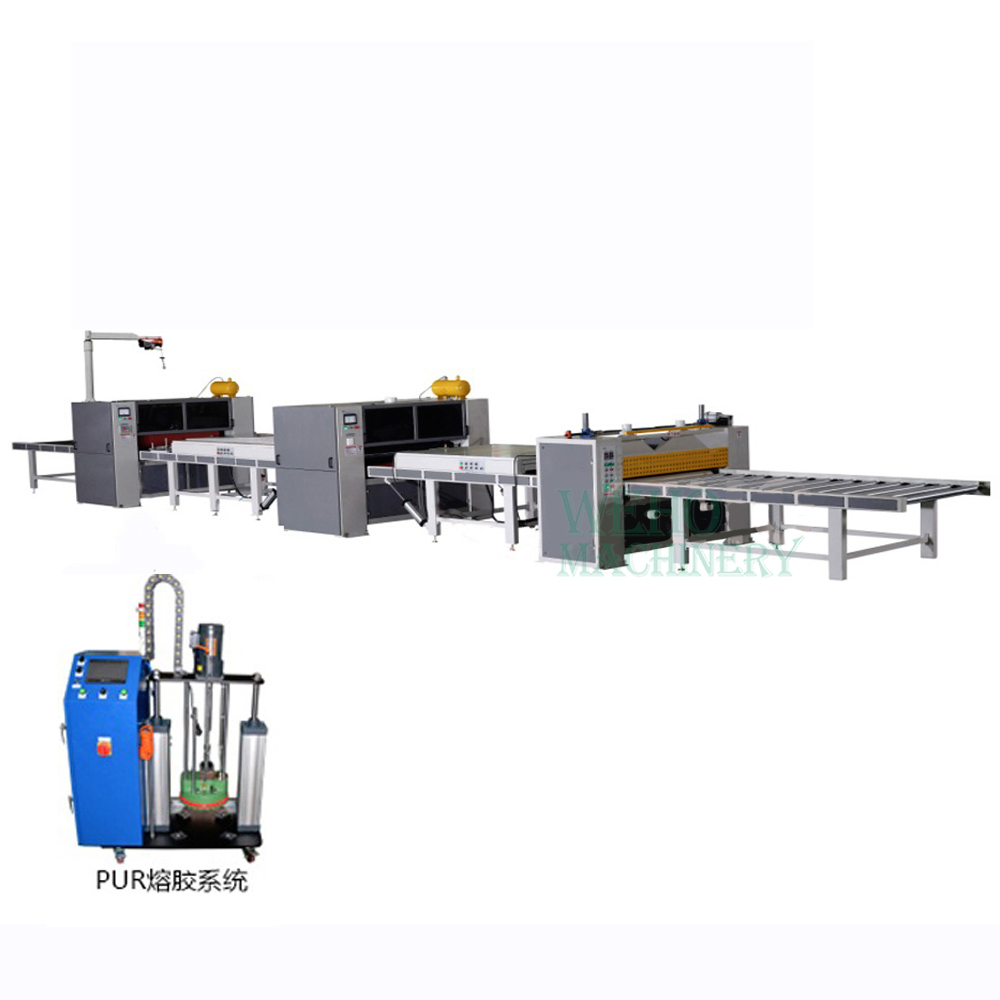

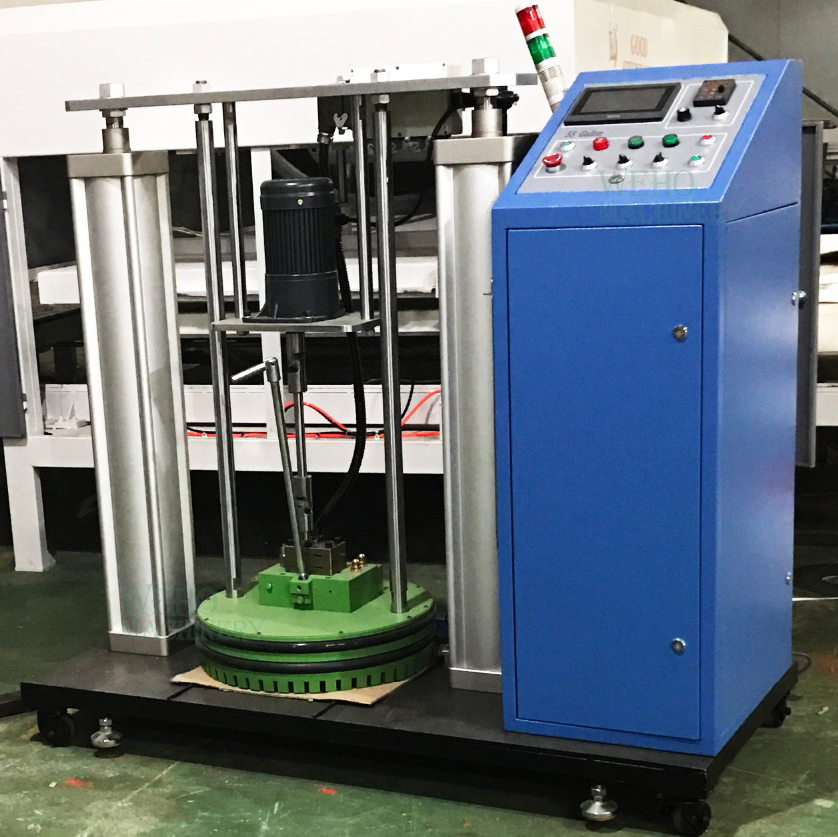

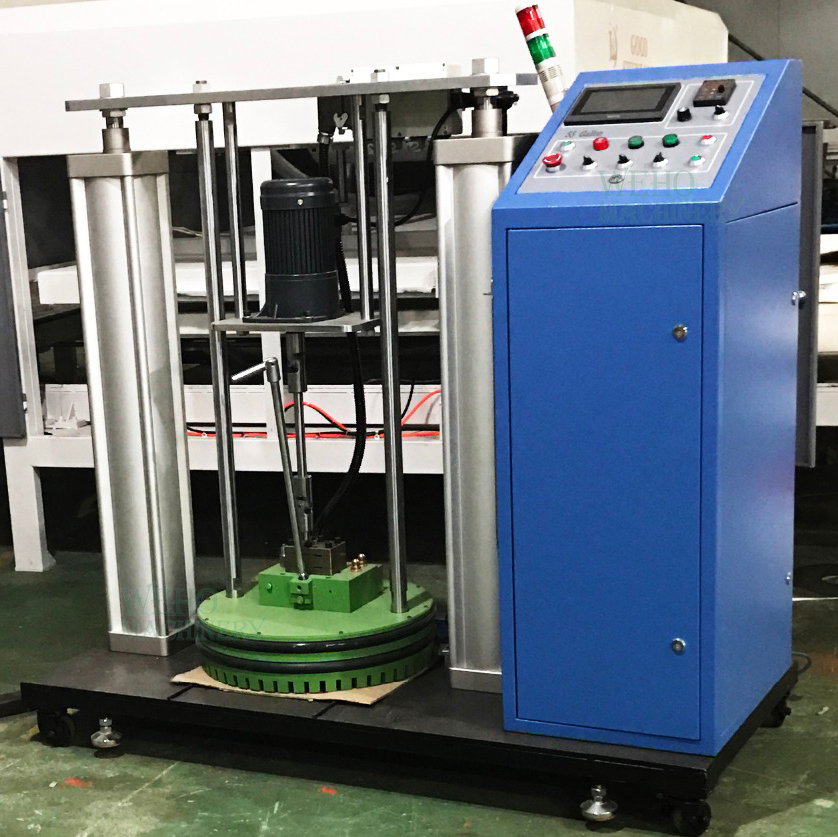

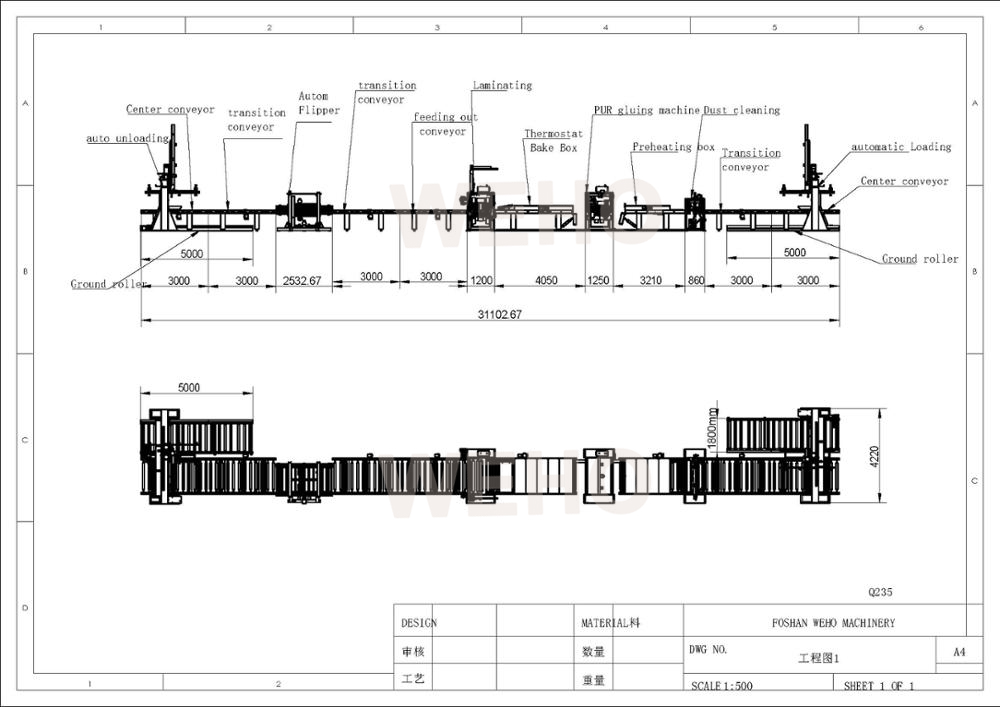

PUR glue hot melt wood furniture panel door laminating line machine

Model:PUR1220;PUR1220AU

Specifications:320 * 1400 mm

Working Width:1220mm

Feed Speed:3-29m/min

Lifting Power:1.5KW x 2

Dimension(L*W*H):19500*2400*1780mm

Power (kW):40

Weight (KG):7500 kg

Specifications:320 * 1400 mm

Working Width:1220mm

Feed Speed:3-29m/min

Lifting Power:1.5KW x 2

Dimension(L*W*H):19500*2400*1780mm

Power (kW):40

Weight (KG):7500 kg

Details

Spare Parts

Inquiry

This production line is mainly aimed at the joint on the board a variety of decorative materials, such as PVC, wood grain paper and so on.

| Technical Data Woodworking & Industrial Pur Laminating Machine | |

| Specifications | 320 * 1400 mm |

| Working Width | 1220mm |

| Feed Speed | 3-29m/min |

| Passing Height | 2.5-50mm |

| Operating Side | right hand;on request left hand |

| Feed Of Boards | right |

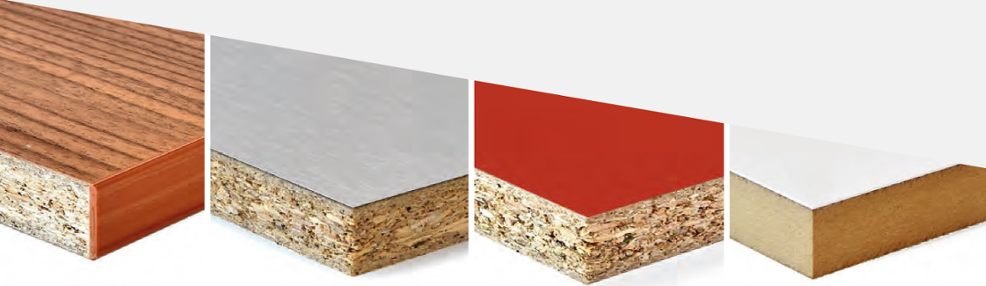

| Material | chipboards/MDF/HDF/Honeycomb boards |

| solid wood boards/sandwich elements | |

| Surface Material | |

| Processing in sheets cut size | PET,PVC foils,Acrylic,HPL,CPL |

| Processing from the roll | PET,PVC foils,Paper foils |

Usable for many different materials flat surface materials and extruded billets can be used manual and/or automatic feeding lamination and upgrading substrates/ for producing composite elements.Pre-heating system, oil heating and keep heat temprature system.used manual and/or automatic feeding lamination and upgrading substrates/ for producing composite elements

The high gloss production line designed according to surface material, base material and size of base work pieces. You provide us more specific information, the machine we design more suitable to your requirement.

Has the speed force and other advantages, so that the processing plate surface smooth without wrinkles, is the ideal equipment.used in large panel factory.

Simple lay-up area to lay-up the surface material,Intuitive operating concept for the complete line,expandibility in the construction kit,Standard,Round brush from the top,IR pre-heating zone.

Automatic loading panel or loading down, save labors. One more roller for pressing again.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines. Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

Door Laminating Line

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.