Maintenance Tips for Your Automatic Saw Blade Sharpening Machine

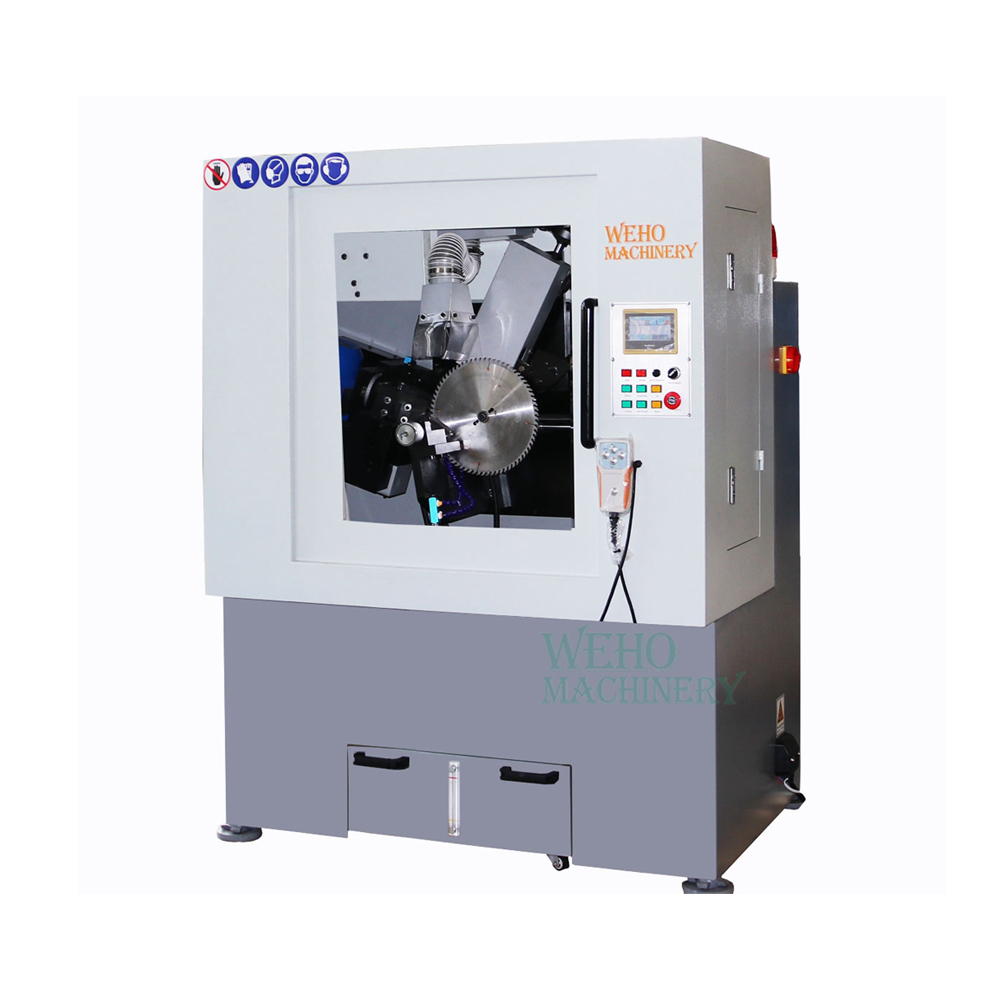

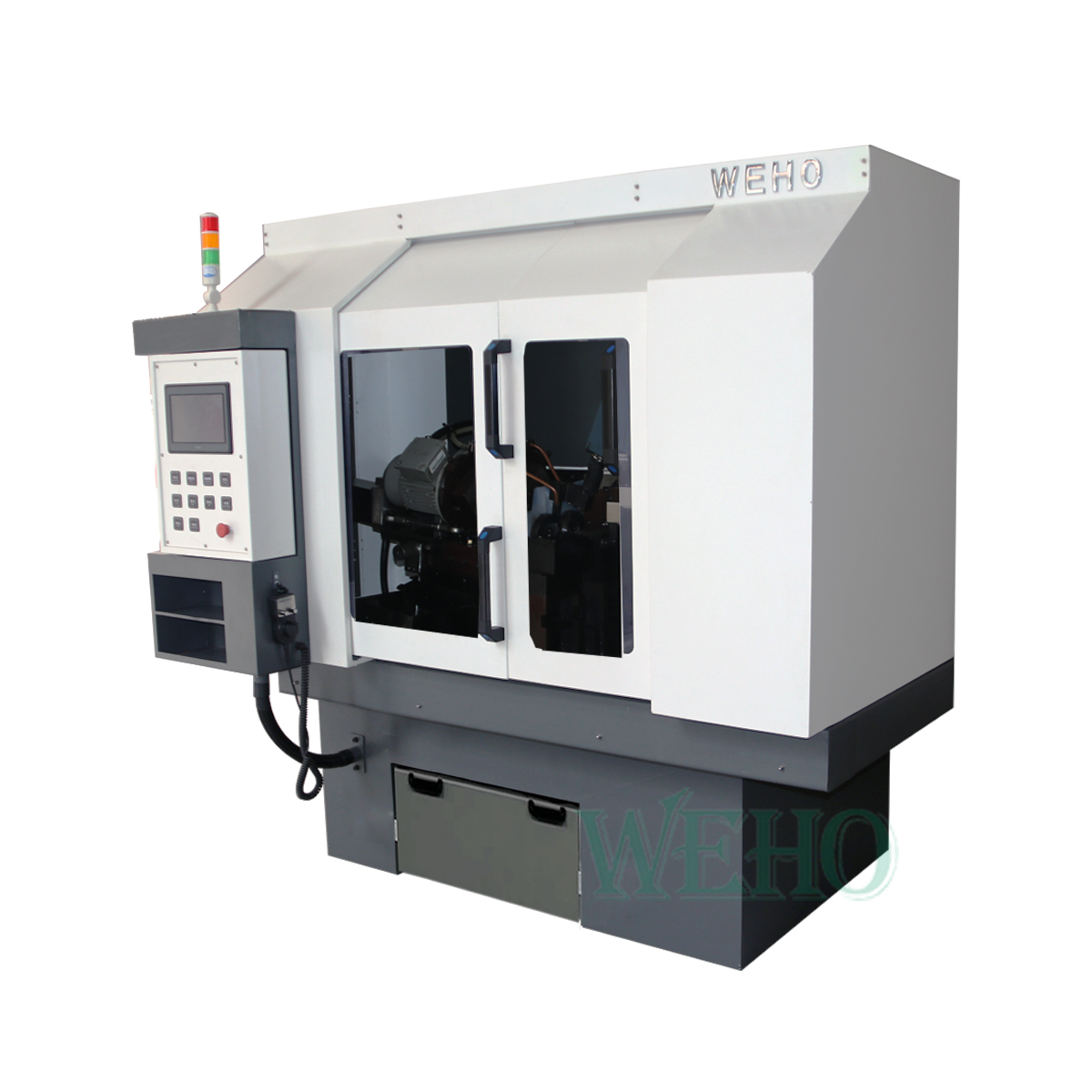

An automatic saw blade sharpening machine is an essential asset for woodworking factories, saw blade resharpening services, and tool maintenance workshops. These machines are designed to restore blade sharpness with precision, consistency, and minimal operator intervention. However, to keep your sharpening equipment in peak condition, regular maintenance is crucial.

Proper upkeep not only extends the life of your machine but also ensures better cutting performance, reduced downtime, and greater return on investment. In this guide, you'll learn practical maintenance tips for automatic saw blade sharpening machines, including daily care, periodic inspection, troubleshooting, and calibration techniques. We'll also explain how WEHO, a trusted manufacturer of saw blade sharpening machines, supports long-term reliability through robust design and OEM-grade components.

Why Regular Maintenance Matters

Maintaining your automatic saw blade sharpening machine is not just about keeping it clean—it's about sustaining accuracy and productivity. Over time, metal dust, coolant residue, and grinding wheel debris can accumulate in sensitive parts, causing wear, vibration, and reduced precision.

Consistent maintenance offers several major benefits:

Improved Precision and Sharpening Quality

Regular cleaning and calibration ensure the grinding wheel remains aligned, resulting in smooth, uniform sharpening across all teeth.

Extended Machine Lifespan

Proper lubrication and component inspection help prevent premature wear on spindles, guide rails, and servo systems.

Reduced Downtime and Repair Costs

Preventive maintenance helps you identify issues early—before they cause serious failures or production interruptions.

Enhanced Safety and Operator Confidence

Machines with well-maintained guards, sensors, and cooling systems operate safely and efficiently.

Daily and Weekly Maintenance Tips

1. Perform a Visual Inspection

Before and after each shift, inspect the machine for loose fasteners, coolant leaks, or signs of abnormal vibration. Confirm that all guards, safety interlocks, and covers are properly in place. If you hear unusual noises, stop the machine immediately and investigate.

2. Keep the Machine Clean

Metal filings and sawdust can easily accumulate on the worktable, grinding area, and control panel. Use a soft brush or low-pressure air to remove debris. Wipe down external surfaces with a clean cloth to prevent corrosion.

Never use high-pressure air directly on bearings or electronics—doing so can force dust into sensitive parts.

3. Check Coolant Levels and Filters

Coolant plays a vital role in maintaining grinding quality and tool temperature. Each day, check the coolant level and top it up if needed. Replace coolant periodically to avoid bacterial growth or clogging. Clean or replace filters to maintain smooth coolant flow.

4. Lubricate Moving Parts

Lubrication is key to preventing friction and wear on linear guideways, lead screws, and other moving components. Apply manufacturer-recommended lubricants to critical parts according to the schedule in your manual. Avoid over-lubrication, as excess oil can attract dust and cause buildup.

5. Test Machine Functions

Run the sharpening machine through a short idle cycle to verify smooth movement of each axis. Listen for unusual sounds in the motor or spindle. Check the emergency stop and ensure all control buttons function correctly.

By following these daily and weekly maintenance steps, you can prevent most common problems before they start.

Monthly and Quarterly Maintenance Routines

For deeper preventive maintenance, a monthly or quarterly inspection is highly recommended. This helps identify wear or misalignment that isn't visible during daily operation.

1. Inspect the Grinding Wheel

Examine the grinding wheel for cracks, glazing, or uneven wear. If necessary, dress or replace it. A true and balanced wheel ensures even sharpening and prevents overheating.

2. Check Spindle Bearings

Listen for noise or vibration that might indicate bearing wear. Monitor spindle temperature during operation—excess heat may suggest lubrication failure or bearing misalignment.

3. Align and Calibrate

Use a reference blade to check tooth geometry and ensure each tooth is ground to the correct height and angle. If the results vary, recalibrate the machine following the OEM guide.

4. Review the Coolant System

Drain and flush the coolant tank, clean hoses and nozzles, and refill with new coolant at the proper ratio. Check the pump for flow consistency and replace filters if clogged.

5. Inspect Electrical Components

Tighten loose connectors, check insulation on cables, and verify that servo drives and sensors respond accurately. Proper electrical integrity ensures stable machine operation.

6. Examine Belts and Couplings

Inspect drive belts for wear or cracks and adjust tension as needed. Make sure motor couplings are securely fastened and properly aligned.

7. Evaluate Safety Devices

Test limit switches, emergency stops, and door interlocks. Any malfunction in these components should be addressed immediately to prevent accidents.

Troubleshooting Common Problems

Even with good maintenance, issues can occasionally occur. Here are some common problems and how to fix them:

- Uneven Tooth Sharpening – Often caused by wheel imbalance or misalignment. Redress the wheel and recalibrate the axes.

- Abnormal Vibration or Noise – Check for loose fasteners, worn bearings, or imbalanced grinding wheels.

- Poor Coolant Flow – Clean filters and flush coolant lines to remove debris or air pockets.

- Overheating Motors or Spindles – Ensure proper lubrication and ventilation. Replace worn components if necessary.

- Sensor or Interlock Errors – Clean dust from optical sensors and verify wiring integrity.

Keeping a maintenance log that records issues and repairs helps track recurring problems and plan replacements before breakdowns happen.

Special Maintenance Tips for WEHO Machines

WEHO is a well-established manufacturer of woodworking and sharpening equipment known for its precision engineering and reliable performance. Their automatic saw blade sharpening machines are designed with advanced control systems, durable components, and easy-to-maintain structures.

Here's how to maximize the performance of a WEHO sharpening machine:

Use OEM Lubricants and Coolants

WEHO machines are built with tight mechanical tolerances that require specific lubrication and coolant types. Always follow the company's manual to avoid premature wear.

Follow WEHO Calibration Protocols

Each WEHO machine is shipped with a calibration reference blade. Periodically check sharpening consistency against this baseline to maintain cutting precision.

Replace Wear Parts on Schedule

Keep a stock of critical spare parts—like belts, bearings, and couplings. WEHO provides genuine OEM components that ensure long-term reliability.

Update Software and Firmware

Some WEHO automatic sharpeners come with CNC or PLC controls. Contact WEHO's support team for firmware updates that improve functionality and safety.

Maintain Service Records

Keeping detailed records of all maintenance and calibration helps preserve your warranty and simplifies future service requests.

By following these practices, you'll extend the lifespan and stability of your WEHO automatic saw blade sharpening machine.

Best Practices for Long-Term Reliability

- Keep your workshop clean and temperature-stable.

- Use vibration isolation pads to stabilize the machine base.

- Train operators to recognize early warning signs like noise, odor, or uneven grinding.

- Avoid overloading the machine beyond its rated capacity.

- Schedule downtime for comprehensive maintenance twice a year.

These preventive maintenance habits ensure that your sharpening system continues to perform accurately and efficiently for years.

Conclusion

Maintaining an automatic saw blade sharpening machine requires consistency, attention to detail, and proper documentation. With a daily cleaning routine, regular inspections, and periodic calibration, you can keep your equipment operating at peak efficiency.

For users of WEHO sharpening machines, following the company's recommended maintenance schedule and using genuine parts will further improve durability and cut quality. By taking a proactive approach, your sharpening machine will deliver precise results, reduce downtime, and maximize productivity—making it one of the most valuable assets in your workshop.