Manual vs Automatic Saw Blade Sharpeners: Which One Should You Buy?

In woodworking, nothing is more essential than a sharp saw blade. A dull blade reduces accuracy, slows production, and can even damage valuable material. To maintain performance, woodworkers and manufacturers rely on a saw blade sharpener. The challenge many face is deciding between a manual saw blade sharpener and an automatic saw blade sharpener.

Both machines have their advantages, but they serve very different needs. In this article, we'll explore the differences, the pros and cons of each option, and how to choose the right solution for your workshop or production line.

Understanding Saw Blade Sharpeners

A saw blade sharpener is designed to restore the cutting edge of blades used in circular saws, table saws, and band saws. By regrinding the teeth to their proper angle and sharpness, the machine extends the life of the blade and ensures consistent cutting quality.

Sharpeners generally fall into two categories:

- Manual saw blade sharpeners – controlled entirely by the operator, suitable for smaller workloads.

- Automatic saw blade sharpeners – motor-driven and programmable, designed for higher efficiency and industrial applications.

Manual Saw Blade Sharpeners

A manual sharpener is the traditional choice for workshops with limited sharpening needs. The operator sets the angle, positions the blade, and sharpens each tooth individually.

Advantages of Manual Sharpeners

Manual sharpeners are often the most affordable option. They are compact, easy to store, and provide the user with direct control over every sharpening pass. For small woodworking shops or hobbyists, this is an attractive solution.

Another advantage is flexibility. Skilled operators can adjust angles according to specific cutting needs, making manual sharpening versatile when dealing with different blade types.

Drawbacks of Manual Sharpeners

However, manual sharpening has clear limitations. It is time-consuming, especially for larger blades or when sharpening multiple blades in one day. Results can also vary depending on the operator's experience and precision. In addition, manual sharpeners are not ideal for large-scale production because they demand significant time and labor.

Automatic Saw Blade Sharpeners

An automatic saw blade sharpener uses motors and programmable settings to complete the sharpening process with minimal operator involvement. Once the blade is installed and parameters are set, the machine sharpens every tooth consistently.

Advantages of Automatic Sharpeners

The biggest benefit of automatic sharpeners is efficiency. They are significantly faster than manual sharpeners, making them ideal for factories, sawmills, and furniture manufacturers that process a large number of blades.

Consistency is another major strength. Because the machine handles the angles and pressure automatically, every tooth is sharpened evenly, resulting in cleaner cuts and longer blade performance. Automatic sharpeners also reduce the reliance on skilled operators, which can save labor costs in the long run.

Drawbacks of Automatic Sharpeners

The main disadvantage is the higher initial investment. These machines are more expensive and require more space in the workshop. For very small woodworking shops with limited sharpening needs, an automatic sharpener may be more than necessary.

Comparing Manual and Automatic Sharpeners

When deciding between manual and automatic machines, it helps to think about your workshop's scale and goals.

A manual saw blade sharpener is the better option if you run a small shop, sharpen blades only occasionally, or want a low-cost solution. It gives you control, requires little space, and gets the job done for low-volume needs.

On the other hand, an automatic saw blade sharpener is a smarter investment if you deal with large quantities of blades, need fast turnaround times, or prioritize consistent quality. While the upfront cost is higher, it quickly pays for itself through labor savings and improved production efficiency.

In short: manual sharpeners are suitable for hobbyists and small woodworking shops, while automatic sharpeners are best for industrial workshops and furniture factories.

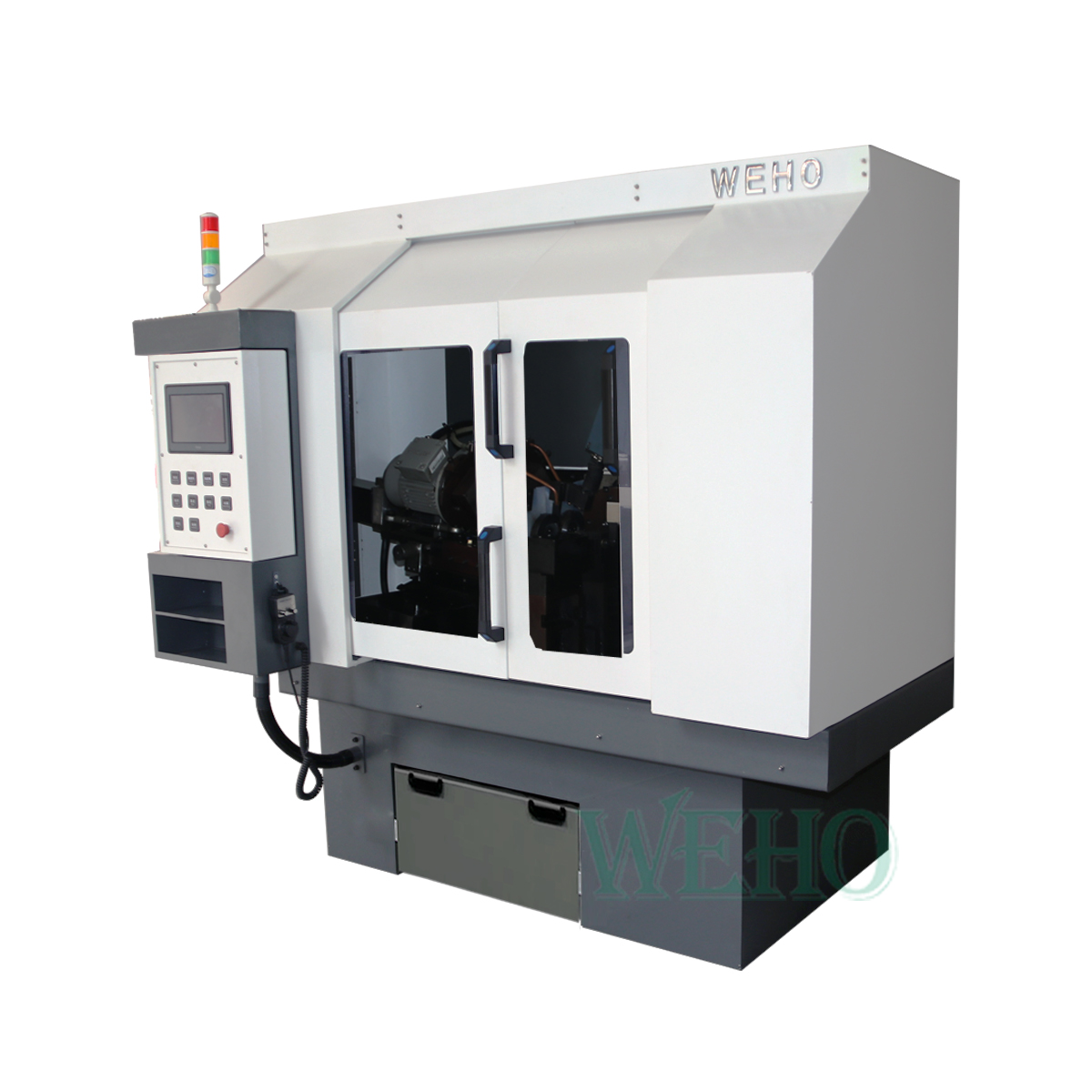

Why WEHO Specializes in Automatic Saw Blade Sharpeners

At WEHO, we have more than 15 years of experience in manufacturing woodworking machinery. Over the years, we have seen how woodworking has shifted from small-scale operations to high-efficiency production lines. This evolution has made automatic saw blade sharpeners the clear choice for professional users.

That is why WEHO focuses exclusively on automatic sharpening solutions. Our machines are designed to help workshops and factories:

- Sharpen faster – Reducing downtime and keeping production on schedule.

- Achieve precision – Ensuring uniform sharpening for smoother, more accurate cuts.

- Save labor costs – Minimizing the need for highly skilled manual work.

- Rely on durability – Heavy-duty construction for long-term industrial use.

By offering automatic sharpeners, we ensure our customers get the most advanced, reliable, and cost-effective solutions tailored to modern woodworking needs.

Conclusion

When comparing manual vs automatic saw blade sharpeners, both options have their place. Manual sharpeners may suit hobbyists and very small workshops, but they are limited in speed and consistency.

For professional woodworking operations, however, the answer is clear: an automatic saw blade sharpener is the best investment. It ensures blades remain sharp, production remains efficient, and results remain consistent.

At WEHO, we provide advanced automatic saw blade sharpening machines designed for furniture factories, woodworking plants, and industrial users who value quality and efficiency. With our expertise and dedication to durable solutions, we help customers achieve sharper blades and sharper results every day.