Investing in a Saw Blade Sharpener: Cost Savings for Furniture Makers

In the world of furniture manufacturing, precision and efficiency define success. Every cut matters, and every piece of wood that goes to waste impacts the bottom line. Among the tools that determine quality and productivity, saw blades are at the very core. However, even the most durable blades wear out over time, becoming dull and less effective. This is where a saw blade sharpener becomes not just a tool, but a strategic investment. For furniture makers, investing in the right saw blade sharpening machine can deliver long-term cost savings, improve cutting accuracy, and ensure consistent production quality.

This article explores how a saw blade sharpener can reduce operating costs, extend the lifespan of blades, and enhance workshop performance, while also highlighting why manufacturers like WEHO provide the ideal solutions for professional woodworkers.

Why Sharp Blades Matter in Furniture Production

Precision and Quality of Cuts

A sharp blade ensures smooth, clean, and accurate cuts. Dull blades not only slow down production but also cause defects such as chipping, rough edges, and uneven cuts. For furniture makers, these imperfections mean wasted materials and rework.

Reduced Waste and Higher Yield

Wood is a valuable resource. A dull blade can increase the kerf width, remove more material than necessary, and result in inaccurate sizing. Sharpening saw blades regularly ensures maximum yield from every piece of timber.

Safety and Efficiency

Operating with dull blades requires greater force and generates more heat, which can damage machinery and pose safety risks to operators. Keeping blades sharp significantly reduces these risks.

The Financial Impact of Dull Saw Blades

Furniture makers often underestimate the hidden costs of dull blades:

- Frequent Blade Replacements: Buying new blades instead of maintaining existing ones quickly increases expenses.

- Increased Machine Wear: Dull blades stress motors, spindles, and bearings, leading to costly repairs.

- Downtime and Lost Productivity: Replacing blades too often or dealing with poor cutting results slows down workflow.

- Material Waste: Even small inaccuracies in cutting accumulate into significant financial losses over time.

By comparison, investing in a saw blade sharpener drastically reduces these costs, offering long-term savings and higher efficiency.

Benefits of Investing in a Saw Blade Sharpener

1. Extending Blade Lifespan

Instead of discarding dull blades, sharpening restores them to near-original condition. A single saw blade can go through dozens of sharpening cycles, reducing the frequency of new purchases.

2. Lower Operational Costs

Sharpened blades reduce power consumption because machines don't need to exert extra force. This translates to lower energy bills and less mechanical strain.

3. Consistent Cutting Quality

Sharpened blades maintain high-quality output, which is critical for producing furniture components that require exact measurements and smooth finishes.

4. Quick ROI (Return on Investment)

For furniture makers with medium to large-scale production, the savings from reduced blade purchases and increased efficiency often pay back the investment in a saw blade sharpening machine within a year.

5. In-House Control Over Maintenance

Having your own sharpener means less reliance on external sharpening services, reducing outsourcing costs and giving you full control over production schedules.

Types of Saw Blade Sharpeners for Furniture Makers

Manual Saw Blade Sharpeners

Best suited for small workshops or DIY users, manual sharpeners are affordable but require more operator skill and time.

Automatic or CNC Saw Blade Sharpeners

For professional furniture manufacturers, CNC saw blade sharpeners deliver precision, repeatability, and speed. They can handle multiple blade types and sharpening angles, making them ideal for large-scale production.

Carbide and TCT Blade Sharpeners

As most furniture makers use TCT (Tungsten Carbide Tipped) saw blades, specialized sharpeners designed for carbide-tipped teeth ensure optimal performance and longevity.

Cost Savings Breakdown: Real-World Example

Consider a medium-sized furniture workshop that uses 50 saw blades annually:

- Without a sharpener: Each blade is replaced 2–3 times a year, costing thousands in replacements.

- With a sharpener: Each blade can be sharpened 15–20 times before replacement. This reduces blade costs by more than 60% annually.

Additionally, sharper blades mean less material waste and higher machine efficiency—further boosting profitability.

How Saw Blade Sharpeners Enhance Sustainability

In today's woodworking industry, sustainability is more than a trend—it's a requirement. By extending the life of blades and reducing waste, saw blade sharpeners contribute to more responsible manufacturing. Furniture makers save money while aligning with eco-friendly practices that customers increasingly value.

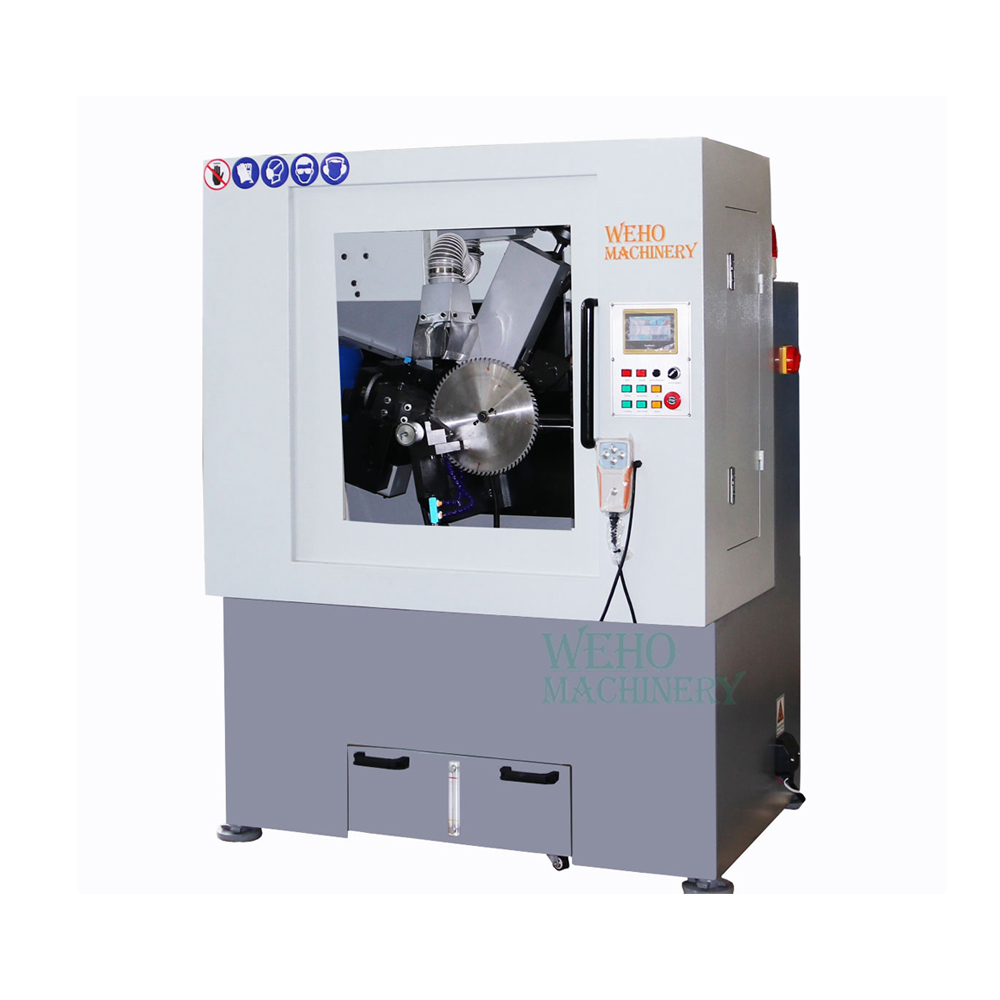

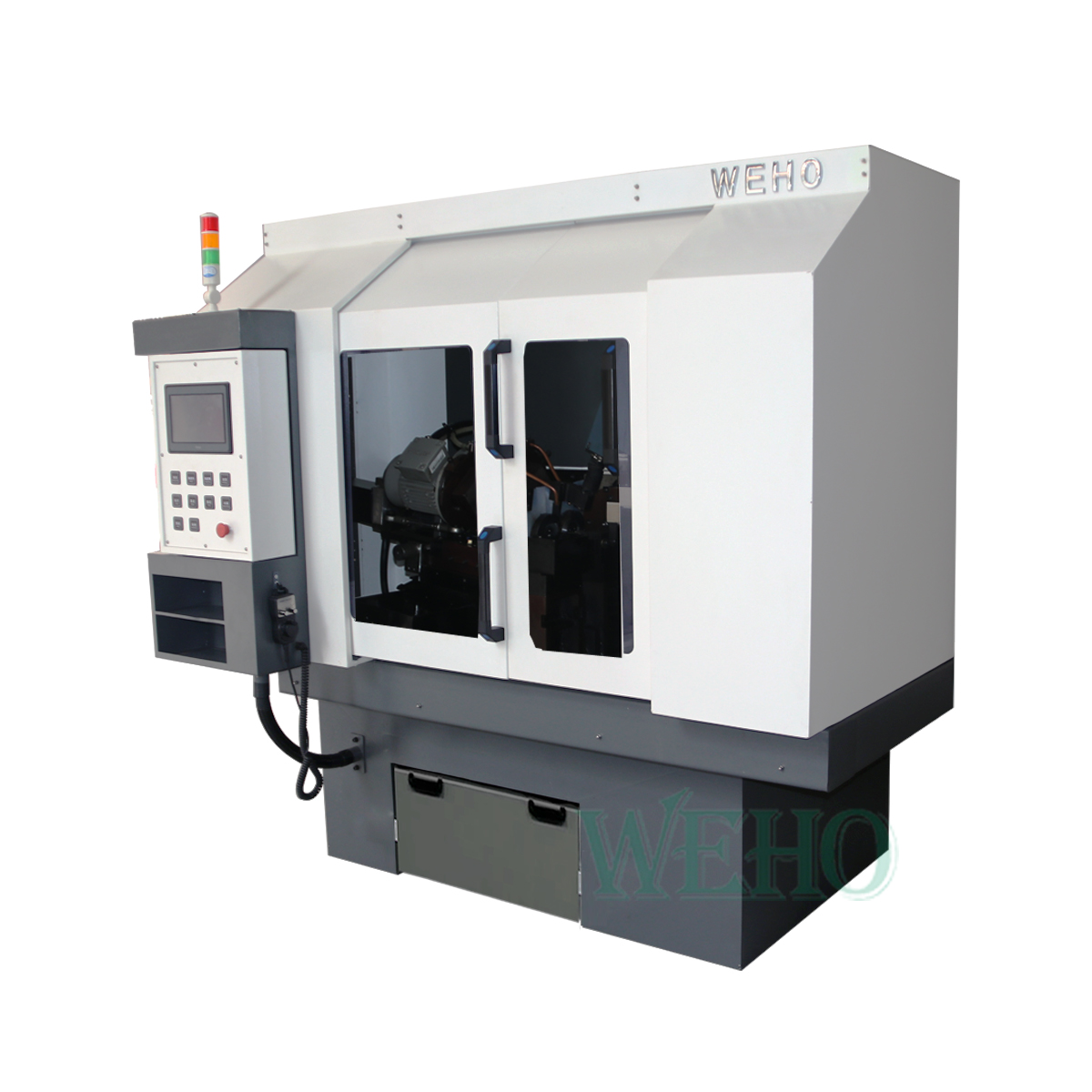

Why Choose WEHO for Your Saw Blade Sharpening Needs

With over 15 years of manufacturing experience, WEHO specializes in providing woodworking machinery, blade sharpening machines, and complete furniture production solutions. Our saw blade sharpeners are designed with:

- High precision CNC technology for consistent sharpening results.

- Durable construction that ensures long service life.

- User-friendly operation for workshops of all sizes.

- Versatility to handle different blade types and sizes.

By investing in a WEHO saw blade sharpener, furniture makers not only save money but also gain a reliable partner in achieving higher efficiency, better cutting results, and long-term growth.

Maintenance Tips for Maximizing Your Sharpener Investment

- Clean the blade before sharpening to avoid debris affecting accuracy.

- Sharpen blades at regular intervals instead of waiting until they are completely dull.

- Use proper cooling systems in CNC sharpeners to prevent overheating.

- Train operators on correct machine handling to extend equipment life.

Conclusion

Investing in a saw blade sharpener is not just about keeping blades sharp—it's about driving long-term savings, efficiency, and quality in furniture manufacturing. From reducing blade replacement costs to ensuring precise, high-quality cuts, the benefits are undeniable. For furniture makers looking to maximize profitability, sharpeners represent one of the smartest investments in a woodworking workshop.

As a trusted name with 15 years of expertise, WEHO continues to support the furniture industry with advanced woodworking machinery and sharpening solutions—helping workshops cut smarter, save costs, and grow sustainably.