Wood Painting Machines Vs Manual Painting: Which Is Right for Your Business?

Selecting the optimal method for finishing wood products is a pivotal decision for any woodworking business. As the industry evolves, companies are faced with the choice between traditional manual painting—valued for its artistry and flexibility—and advanced wood painting machines, which promise speed, consistency, and scalability. Understanding the strengths of each approach is essential to align your production process with your unique business goals, customer expectations, and growth plans.

The Evolution of Wood Finishing

Wood finishing has undergone a significant transformation in recent decades. As businesses strive for greater efficiency, consistency, and scalability, the tools and technologies used for painting wood have evolved. Today, the choice between wood painting machines and manual painting methods is a strategic decision that can shape the future of any woodworking business. Understanding the strengths of each approach is essential for making an informed choice that aligns with your company's goals and growth trajectory.

Manual Painting: The Artisanal Touch

Manual painting remains a cornerstone of the woodworking industry, especially for businesses that prioritize craftsmanship and customization. Skilled artisans use brushes, rollers, or spray guns to apply paints, stains, and finishes, allowing for a high degree of control over the final appearance.

Flexibility and Customization

One of the greatest strengths of manual painting is its adaptability. Craftsmen can easily switch between different colors, finishes, and techniques to meet unique customer demands. This flexibility is especially valuable for businesses that produce bespoke furniture, limited-edition pieces, or items requiring intricate detailing. For example, a custom furniture maker can offer a wide range of finishes, from distressed vintage looks to high-gloss modern styles, all tailored to the customer's specifications.

Artistic Expression and Quality Control

Manual painting allows for a level of artistic expression that machines cannot easily replicate. Skilled painters can create subtle gradients, textures, and effects that enhance the natural beauty of the wood. This hands-on approach also enables immediate quality control—painters can spot imperfections and make adjustments on the fly, ensuring that each piece meets the highest standards.

Cost-Effectiveness for Small Batches

For businesses with low production volumes or those just starting out, manual painting is often the most cost-effective option. The initial investment is minimal, limited to basic tools and materials. This makes it possible for small workshops to offer high-quality finishes without the financial burden of purchasing and maintaining expensive machinery.

Building Brand Value

Hand-painted wood products often carry a sense of authenticity and exclusivity. Customers appreciate the craftsmanship and attention to detail that comes with manual finishing, which can become a key selling point and help build a strong brand reputation. Businesses that emphasize artisanal quality can command higher prices and foster customer loyalty.

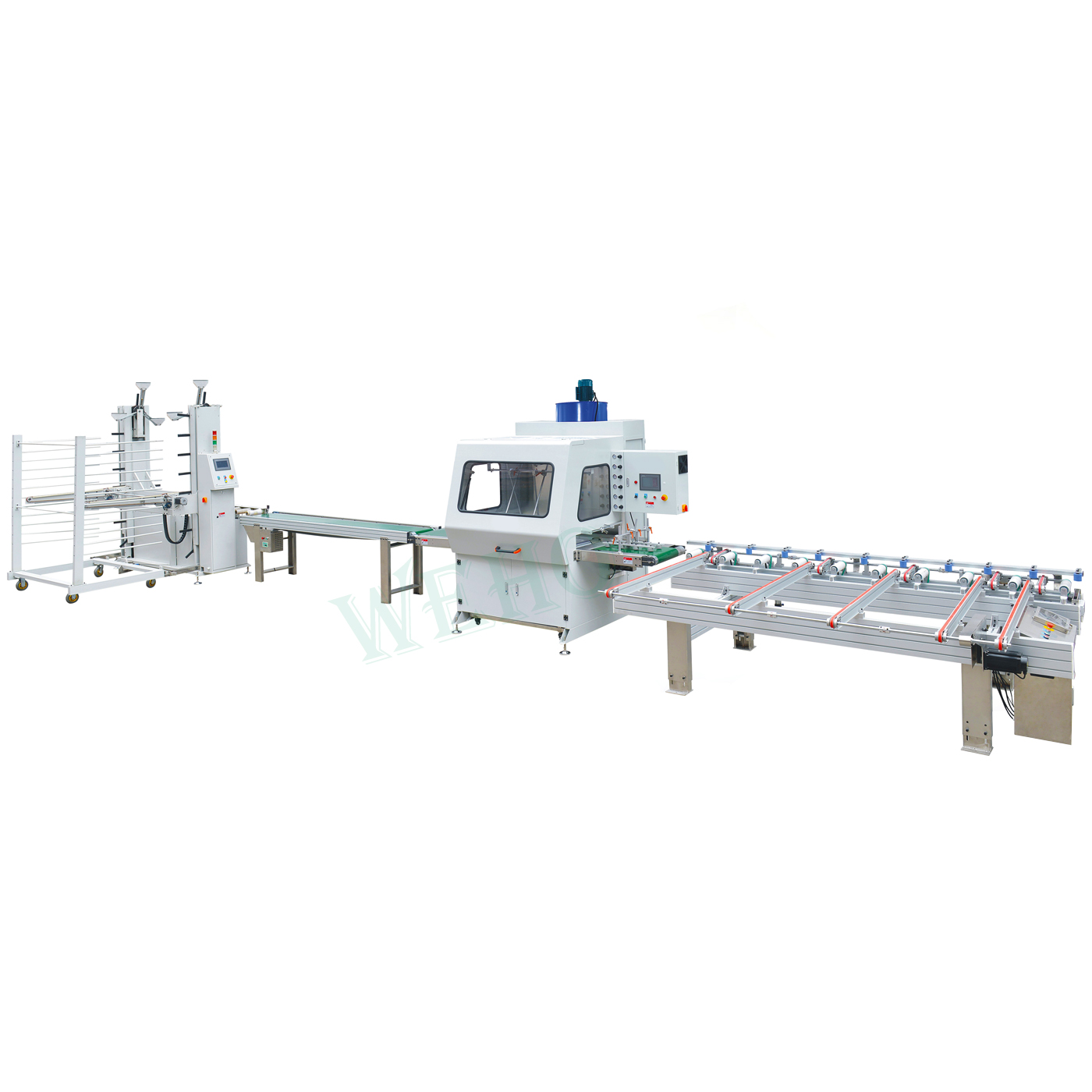

Wood Painting Machines: Precision and Productivity

As demand for wood products grows and competition intensifies, many businesses are turning to automation to streamline operations and boost output. Wood painting machines represent the forefront of this technological shift, offering a range of benefits for manufacturers focused on scale and efficiency.

High-Speed Production

Wood painting machines are designed for speed and throughput. Automated spray systems, conveyor lines, and robotic arms can coat large volumes of wood panels, furniture components, or decorative items in a fraction of the time required for manual painting. This rapid processing capability is essential for businesses serving large markets or fulfilling bulk orders on tight deadlines.

Consistent Quality

One of the primary advantages of automation is the ability to deliver consistent, repeatable results. Machines are programmed to apply precise amounts of paint or finish, ensuring uniform coverage and color across every piece. This consistency is crucial for manufacturers who must meet strict quality standards or supply products to retailers with rigorous specifications.

Material Efficiency

Modern wood painting machines are engineered to maximize material usage and minimize waste. Automated systems can adjust spray patterns, control flow rates, and recover overspray, resulting in significant savings on paints and finishes. These efficiencies not only reduce costs but also support sustainability initiatives by lowering the environmental impact of production.

Scalability and Growth

For businesses planning to expand, wood painting machines offer a clear path to scalability. Automated equipment can be integrated into larger production lines, allowing companies to increase capacity without proportionally increasing labor costs. As demand grows, additional machines or advanced features—such as multi-axis robots or computer-controlled color mixing—can be added to further enhance productivity.

Enhanced Workplace Safety

Automation also contributes to a safer working environment. By handling the application of potentially hazardous paints and finishes, machines reduce workers' exposure to fumes and chemicals. This not only protects employee health but can also help businesses comply with occupational safety regulations.

Key Considerations for Your Business

Selecting the right painting method involves a careful assessment of your business model, production requirements, and long-term objectives. Here are several factors to consider:

Production Volume

Low to Medium Volume: Manual painting is well-suited for small batches, custom projects, and businesses that prioritize flexibility.

High Volume: Wood painting machines are ideal for companies with large-scale production needs, where speed and consistency are paramount.

Product Complexity

Custom and Intricate Designs: Manual painting excels when products require artistic finishes, unique textures, or frequent changes in color and style.

Standardized Products: Automated machines are best for uniform items that benefit from consistent application and minimal variation.

Budget and Investment

Initial Costs: Manual painting requires a lower upfront investment, making it accessible for startups and small workshops.

Long-Term Savings: While wood painting machines involve higher initial costs, they offer long-term savings through reduced labor, material efficiency, and increased output.

Workforce and Skills

Skilled Artisans: If your business relies on experienced painters, manual methods can leverage their expertise for superior finishes.

Technical Operators: Automation requires staff trained to operate, maintain, and troubleshoot machinery, which may involve additional training or hiring.

Brand Positioning

Artisanal Appeal: Businesses that market themselves on craftsmanship and uniqueness will benefit from the story and value of hand-painted products.

Mass Market Reach: Companies targeting broad markets with standardized products will find automation more aligned with their goals.

Conclusion

Choosing between wood painting machines and manual painting is not a one-size-fits-all decision. Each method offers distinct advantages that cater to different business models, production scales, and customer expectations.

Ultimately, the right choice will empower your business to deliver exceptional wood products, satisfy your customers, and thrive in a competitive market.