5 Reasons Every Furniture Factory Needs a Carbide Saw Blade Sharpening Machine

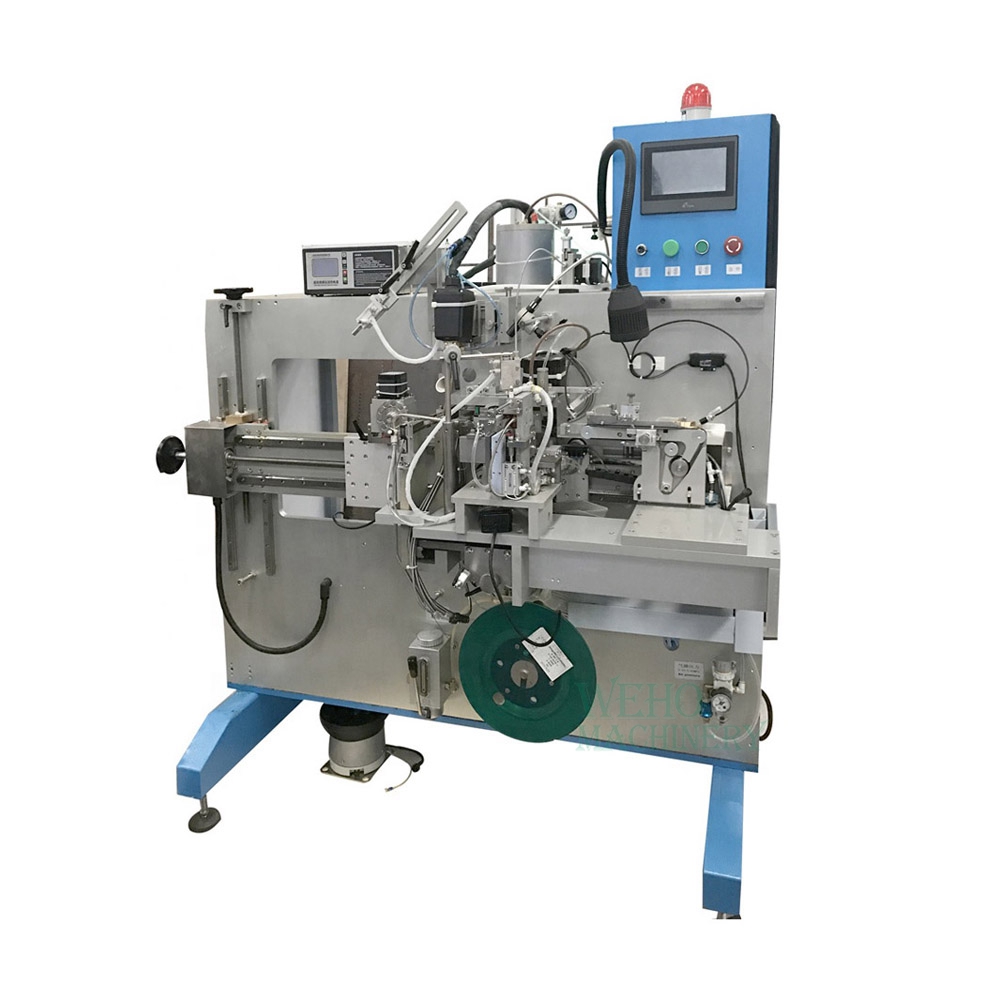

In the competitive world of furniture manufacturing, efficiency, precision, and cost control are critical to staying ahead. One of the most overlooked but essential investments in any woodworking factory is a carbide saw blade sharpening machine. These machines are specifically designed to maintain and restore the sharpness of carbide-tipped saw blades, ensuring smooth cutting performance and extending the life of blades.

For over 15 years, WEHO has specialized in woodworking machinery and sharpening solutions, helping furniture manufacturers worldwide improve productivity and reduce operational costs. In this article, we will explore five compelling reasons why every furniture factory should consider adding a carbide saw blade sharpening machine to their production line.

1. Improved Cutting Precision and Product Quality

In furniture manufacturing, accuracy is non-negotiable. Whether you are producing tables, cabinets, flooring, or decorative pieces, a precise cut determines the final quality of the product. A dull saw blade often results in:

- Rough or chipped edges

- Inconsistent cuts

- Increased rejection rates

A carbide saw blade sharpening machine restores the blade's sharpness, ensuring that each cut is clean and accurate. This precision not only reduces material waste but also enhances the overall finish of the furniture.

Furniture factories that rely on sharp blades experience fewer production defects and enjoy consistent product quality. By incorporating an automatic carbide saw blade sharpener, you can achieve repeatable accuracy that manual sharpening simply cannot match.

2. Cost Savings Through Extended Blade Life

Carbide saw blades are a significant investment for any woodworking operation. Replacing them frequently can quickly increase operational expenses. A saw blade sharpening machine maximizes the lifespan of each blade by allowing it to be resharpened multiple times before replacement becomes necessary.

Instead of discarding a blade after it becomes dull, sharpening restores its cutting edge, saving your factory hundreds or even thousands of dollars annually.

At WEHO, our advanced carbide saw blade sharpening machines are engineered to deliver precise grinding, ensuring uniform sharpness across the blade teeth. This results in extended blade usability and substantial cost savings for furniture manufacturers.

3. Increased Productivity and Reduced Downtime

Time is money in manufacturing. A dull blade slows down the cutting process, forcing operators to make repeated passes and increasing overall cycle times. In some cases, production may need to pause entirely for blade replacement or outsourced sharpening services.

By installing an in-house carbide saw blade sharpening machine, factories can:

- Sharpen blades immediately when needed

- Avoid long wait times associated with third-party sharpening services

- Keep production running without costly interruptions

This directly translates into higher productivity and smoother operations. Automated sharpening machines also minimize manual labor, freeing up workers to focus on other essential tasks within the workshop.

4. Versatility for Different Saw Blades

Modern furniture factories use a variety of cutting tools depending on the type of material and the complexity of the design. From circular saw blades to specialized carbide-tipped tools, each blade requires proper maintenance to deliver consistent results.

A carbide saw blade sharpening machine offers versatility by accommodating different blade sizes and tooth configurations. This flexibility makes it an indispensable piece of equipment in workshops that need to handle diverse production demands.

WEHO's sharpening solutions are designed with user-friendly controls and adaptable features, ensuring that furniture manufacturers can maintain different types of saw blades with ease.

5. Long-Term Investment in Efficiency and Competitiveness

In today's furniture industry, where competition is fierce and customer expectations are high, efficiency and consistency are vital. Investing in a carbide saw blade sharpening machine is not just about saving money on blade replacements — it is about strengthening your long-term competitive edge.

Key long-term benefits include:

- Lower operating costs

- Improved sustainability by reducing waste

- Consistent product quality

- Enhanced reputation for precision and reliability

Factories equipped with automatic saw blade sharpening machines are better positioned to meet large orders, adapt to customer demands, and maintain a strong foothold in the market.

Why Choose WEHO as Your Sharpening Machine Partner?

With over 15 years of experience in woodworking machinery manufacturing, WEHO has become a trusted name in the industry. Our carbide saw blade sharpening machines are engineered with advanced technology, durable components, and user-friendly designs to support the demanding needs of modern furniture factories.

By choosing WEHO, you benefit from:

- Professional manufacturing expertise in woodworking machinery

- Reliable after-sales service and technical support

- Tailored solutions for furniture manufacturing workshops

- Proven track record of helping factories improve efficiency

Whether you are running a small woodworking shop or a large-scale furniture factory, WEHO provides the right machinery to optimize your production line.

Conclusion

Every furniture factory depends on sharp, reliable saw blades to produce high-quality products efficiently. A carbide saw blade sharpening machine is not just an optional tool — it is an essential investment that brings precision, cost savings, productivity, versatility, and long-term competitiveness to your operations.

For manufacturers seeking advanced, durable, and efficient sharpening solutions, WEHO stands ready to deliver. With our 15 years of industry expertise, we help furniture factories worldwide achieve excellence in woodworking.