Saw Sharpening Machine vs Manual Sharpening: Which Is Better?

When it comes to maintaining the performance and longevity of your saw blades, the method you choose for sharpening can make a significant difference. The debate between saw sharpening machines and manual sharpening is a longstanding one in the woodworking and metalworking industries. Each method has its own unique advantages, challenges, and ideal use cases. In this article, we will explore both approaches in depth, analyzing their efficiency, precision, cost-effectiveness, and suitability for different users. By the end, you will have a clear understanding of which method best fits your needs—and why many professionals are turning to trusted brands like WEHO for their sharpening solutions.

The Importance of Saw Blade Sharpening

A sharp saw blade is essential for clean, accurate cuts and efficient operation. Dull blades not only slow down your work but also increase the risk of accidents and can damage your materials. Regular sharpening restores the blade's edge, optimizes cutting performance, and extends the blade's usable life. The method you use to sharpen your blades will impact both the quality of your results and the overall cost of your operations.

Manual Sharpening: Tradition and Craftsmanship

Manual sharpening is the traditional method, often favored by craftsmen, hobbyists, and those who appreciate hands-on work. This process typically involves using files, whetstones, or specialized hand tools to restore the saw's cutting edge. The sharpener must carefully follow the blade's original tooth geometry, maintaining the correct angles and ensuring each tooth is evenly sharpened.

Advantages of Manual Sharpening:

Low Initial Investment: Manual sharpening requires minimal equipment, making it accessible for individuals or small workshops with limited budgets.

Full Control: Skilled operators can adjust the sharpening process for specific blade types, tooth profiles, or custom requirements, which is especially valuable for unique or vintage saws.

Portability: Manual tools are lightweight and can be used anywhere, making them ideal for on-site sharpening or fieldwork.

Satisfaction and Skill Development: Many enjoy the craftsmanship and satisfaction that comes from sharpening a blade by hand, as it fosters a deeper understanding of tool maintenance.

Challenges of Manual Sharpening:

Time-Consuming: Sharpening a saw blade by hand, especially larger or more complex blades, can take considerable time and effort.

Skill-Dependent: Achieving consistent results requires experience, a steady hand, and an eye for detail. Inexperienced users may inadvertently damage the blade or create uneven teeth.

Inconsistent Results: Even skilled sharpeners can have variations from tooth to tooth, which may affect cutting performance.

Limited Scalability: For businesses or workshops dealing with multiple blades, manual sharpening is often impractical due to its slow pace.

Saw Sharpening Machines: Precision and Efficiency

Saw sharpening machines are designed to automate and standardize the sharpening process. These machines use abrasive wheels, guides, and adjustable settings to quickly and accurately restore the edge of each tooth. Modern machines, such as those produced by WEHO, are equipped with advanced features that ensure optimal results with minimal user intervention.

Advantages of Saw Sharpening Machines:

Consistent Precision: Machines deliver uniform sharpening across every tooth, ensuring optimal performance and extending blade life.

Time Efficiency: Automated processes dramatically reduce the time needed to sharpen a blade, making it feasible to handle large volumes or frequent sharpening needs.

Ease of Use: Basic training is sufficient for operators to achieve professional results, reducing reliance on specialized skills.

Long-Term Cost Savings: Although the initial investment is higher, machines minimize labor costs and reduce the frequency of blade replacement, resulting in significant savings over time.

Versatility: Modern sharpening machines can accommodate a wide range of blade types and sizes, from circular saws to band saws and more.

Safety: By minimizing manual handling of blades, machines reduce the risk of accidents and injuries.

Challenges of Saw Sharpening Machines:

Higher Upfront Cost: Purchasing a quality sharpening machine requires a significant investment, which may not be justifiable for occasional users.

Space and Power Requirements: Machines require dedicated workspace and access to electricity, which may not be feasible in all environments.

Maintenance: Like any equipment, sharpening machines require regular maintenance to ensure optimal performance and longevity.

Which Method Is Better?

The answer depends largely on your specific needs, scale of operation, and long-term goals.

If you are a hobbyist, a craftsman working with unique or vintage saws, or someone who only occasionally needs to sharpen blades, manual sharpening may be the right choice. It allows for customization, requires minimal investment, and offers the satisfaction of hands-on craftsmanship. However, you must be prepared to invest time and effort into developing your sharpening skills, and accept that results may sometimes vary.

On the other hand, if you operate a professional workshop, sawmill, or manufacturing facility where efficiency and consistency are paramount, a saw sharpening machine is the clear winner. The ability to quickly and accurately sharpen multiple blades not only boosts productivity but also ensures your tools are always performing at their best. Over time, the investment in a machine pays off through reduced labor costs, extended blade life, and improved cutting quality.

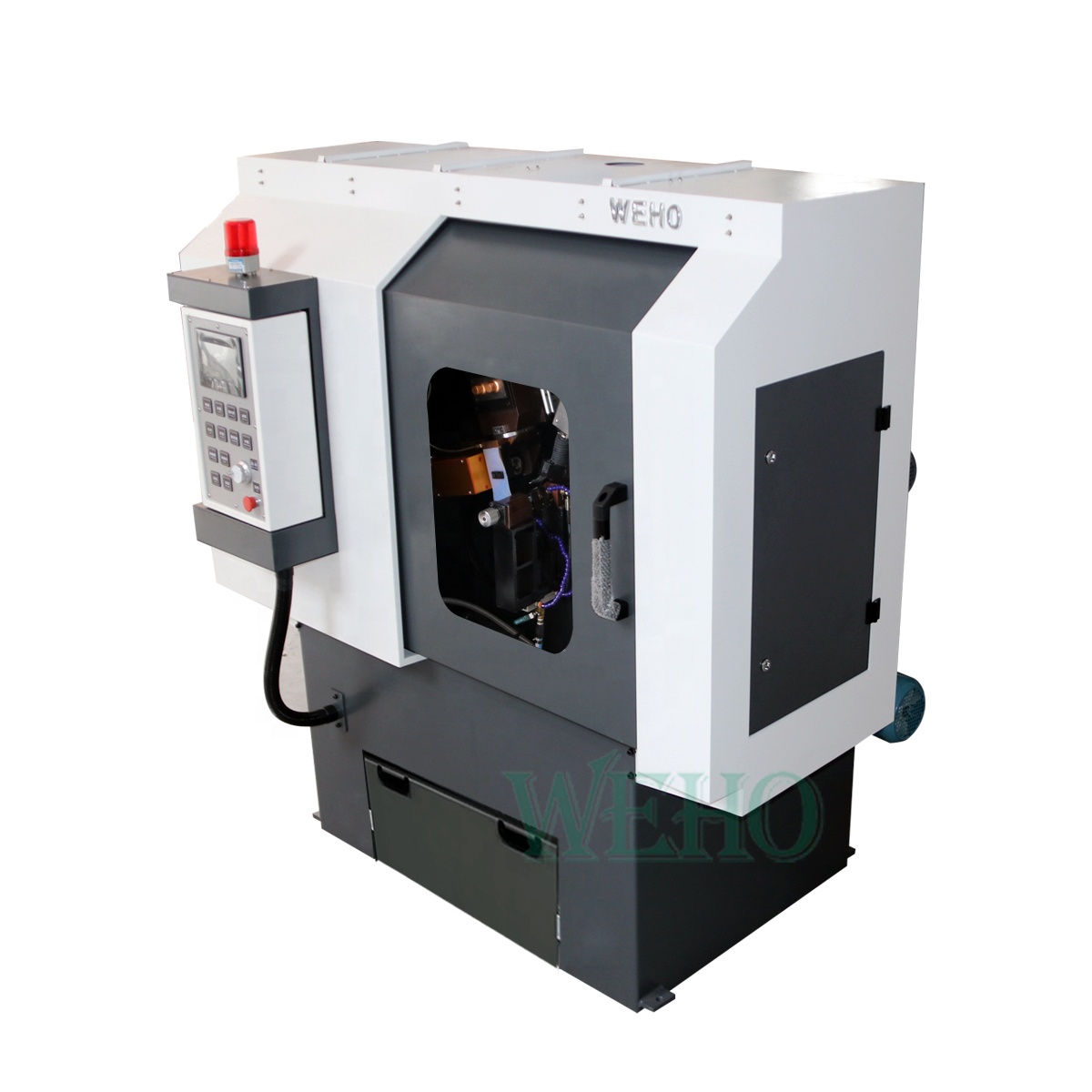

Why WEHO Is the Trusted Choice for Saw Sharpening Machines

For those considering the move to automated sharpening, WEHO stands out as a leading manufacturer of high-quality saw sharpening machines. WEHO's products are renowned for their precision engineering, user-friendly controls, and robust construction. Whether you are sharpening circular saws, band saws, or specialized blades, WEHO offers machines that cater to a wide range of requirements.

Key reasons to choose WEHO:

Advanced Technology: WEHO machines feature intelligent controls and precise adjustment mechanisms, ensuring every tooth is sharpened to perfection.

Comprehensive Range: From entry-level models for small workshops to industrial-grade solutions for large-scale operations, WEHO has a machine to fit every need.

Reliable Support: WEHO provides extensive after-sales service, technical support, and training, helping customers maximize the value of their investment.

Proven Performance: Trusted by professionals worldwide, WEHO machines are built to deliver consistent results, even under demanding conditions.

Cost-Effectiveness: By extending blade life and minimizing downtime, WEHO sharpening machines help businesses achieve significant long-term savings.

Conclusion

Both manual sharpening and saw sharpening machines have their place in the world of blade maintenance. Manual sharpening offers flexibility, low cost, and a sense of craftsmanship, making it suitable for occasional use or specialized blades. However, for those seeking precision, efficiency, and scalability, investing in a saw sharpening machine is the superior choice.

If you are ready to enhance your blade maintenance process, reduce costs, and achieve flawless results, consider exploring WEHO's range of saw sharpening machines. With the right equipment, you can ensure your saw blades are always sharp, your work is always precise, and your business is always moving forward.