Top 10 Tips for Using a Circular Saw Blade Grinder Effectively

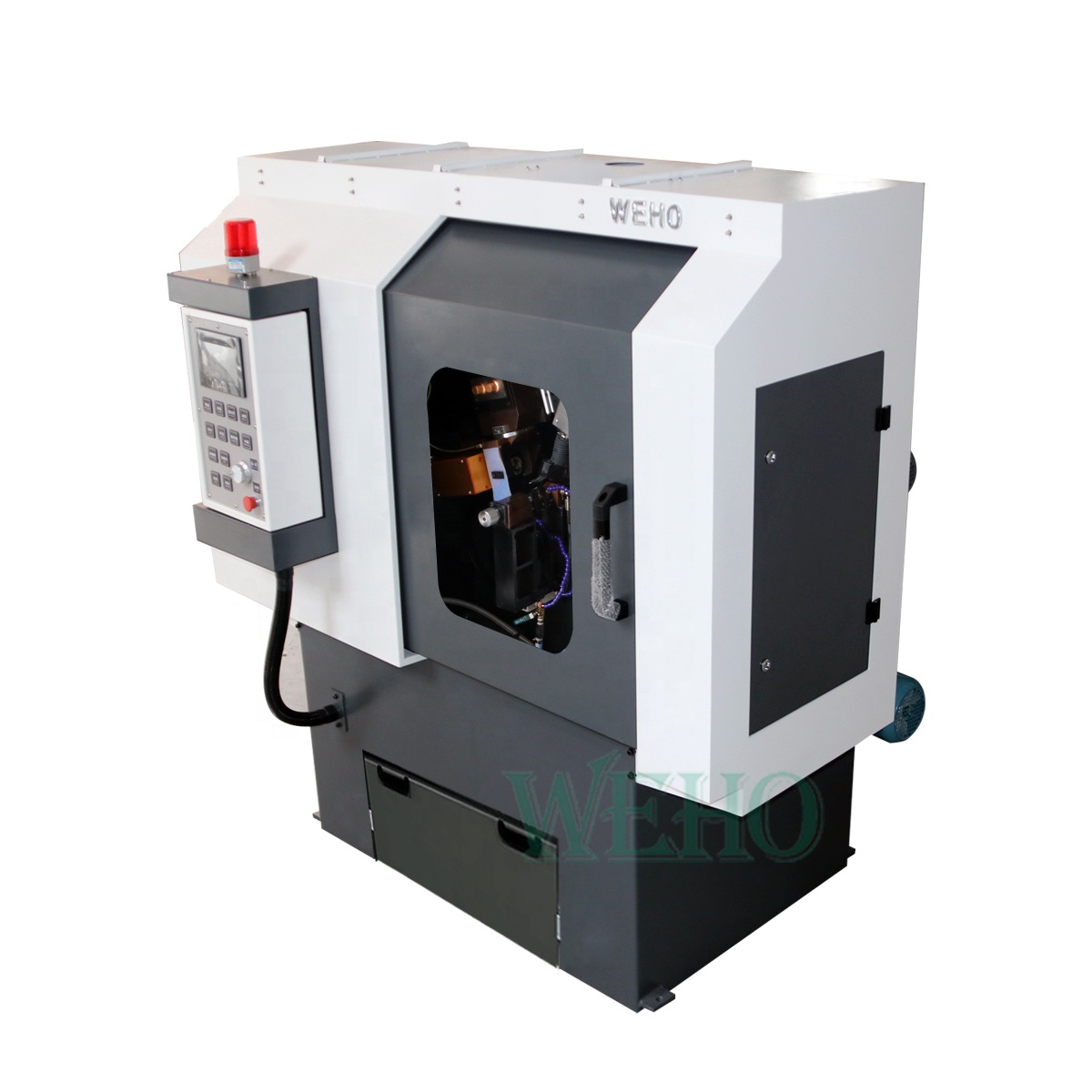

A circular saw blade grinder is an indispensable tool for anyone serious about woodworking, metalworking, or industrial manufacturing. Whether you're sharpening carbide-tipped saw blades, maintaining your woodworking tools, or optimizing your production line, knowing how to use a circular saw blade grinder effectively will extend blade life, improve cut quality, and boost workshop efficiency. This comprehensive guide covers the top 10 expert tips, integrates essential industry keywords, and introduces why WEHO is the go-to brand for sharpening solutions.

1. Select the Right Circular Saw Blade Grinder for Your Application

Choosing the best circular saw blade grinder depends on your blade material, diameter, and tooth type. For instance, a carbide saw blade sharpener is ideal for carbide-tipped blades, while a high-speed steel blade grinder suits HSS blades. Consider features like automatic feed, adjustable grinding angles, and compatibility with various blade sizes. WEHO offers a full range of industrial and workshop-grade grinders to meet diverse needs.

2. Prioritize Safety During Every Operation

Always wear safety goggles, gloves, and hearing protection when operating a saw blade sharpening machine. Ensure the grinder's guards are in place, and never leave the machine unattended while running. Keeping your workspace clean and well-lit reduces the risk of accidents. WEHO grinders are designed with enhanced safety features for peace of mind.

3. Thoroughly Clean and Inspect Blades Before Sharpening

Before placing a blade on the saw blade grinder, remove pitch, resin, and debris using a soft brush and blade cleaner. Inspect for cracks, missing teeth, or warping. Clean blades ensure smoother grinding and prolong the life of both the blade and the grinding wheel.

4. Set the Correct Grinding Angles and Tooth Geometry

Precision is key in saw blade sharpening. Adjust the grinder to match the manufacturer's recommended hook angle, top bevel, and tooth pitch. Advanced grinders like WEHO's CNC models allow for precise, repeatable settings, ensuring every tooth is sharpened uniformly for optimal cutting performance.

5. Use the Appropriate Grinding Wheel for Your Blade

Different blades require different grinding wheels. Use a diamond grinding wheel for carbide-tipped blades and a CBN wheel or aluminum oxide wheel for HSS blades. Using the correct wheel not only improves sharpening results but also prevents premature wear on your equipment.

6. Avoid Overheating the Blade During Grinding

Excessive heat can damage blade temper and cause warping or micro-cracks. Apply light, steady pressure and allow the wheel to do the work. Many WEHO grinders feature automatic cooling systems or water-based lubrication to dissipate heat and protect your blades.

7. Secure the Blade Firmly for Accurate Sharpening

Proper clamping is essential. Mount the blade securely on the circular saw blade grinder using the right adapters or sleeves. WEHO's machines use pneumatic clamps and adjustable fixtures to ensure vibration-free, stable grinding, resulting in a consistent edge on every tooth.

8. Maintain Your Circular Saw Blade Grinder Regularly

Regular maintenance ensures longevity and reliable performance. Clean the grinder after each use, check for worn parts, and lubricate moving components as recommended. WEHO grinders are engineered for easy maintenance, with accessible parts and automatic lubrication systems to minimize downtime.

9. Sharpen Blades at the Right Time

Don't wait until blades are completely dull. Regular sharpening maintains cutting efficiency, reduces material waste, and extends blade life. Monitor blade performance and schedule sharpening based on usage frequency and material type. WEHO's high-speed automatic grinders make it easy to keep your entire blade inventory sharp and ready.

10. Invest in Quality: Why Choose WEHO for Your Saw Blade Sharpening Needs

When it comes to precision saw blade sharpening, WEHO stands out for its reliability, advanced technology, and customer support. Here's why professionals worldwide trust WEHO:

Versatility: Suitable for a wide range of blades, including circular saw blades, carbide-tipped blades, and HSS blades.

Automation: CNC controls and automatic feed systems reduce manual labor and guarantee consistent results.

Durability: Built with industrial-grade materials for long-term, heavy-duty use.

User-Friendly: Intuitive controls and ergonomic design make operation simple for both beginners and experts.

Comprehensive Support: Backed by expert technical assistance and robust warranties.

WEHO's circular saw blade grinders help you achieve razor-sharp results, improve productivity, and reduce operational costs. If you're looking for a dependable solution for your workshop or industrial facility, WEHO is your trusted partner.

Conclusion

Mastering the use of a circular saw blade grinder is vital for anyone who values precision, safety, and efficiency in blade maintenance. By following these ten expert tips and choosing a reliable brand like WEHO, you ensure your blades remain sharp, your cuts stay clean, and your workshop operates at peak performance. Explore WEHO's complete line of sharpening solutions to elevate your productivity and achieve professional results every time.

Ready to upgrade your sharpening process? Discover the advantages of WEHO's circular saw blade grinders and bring your workshop to the next level!