Top 7 Features to Look for in a Circular Saw Grinding Machine

When it comes to maintaining the sharpness and performance of circular saw blades, choosing the right grinding machine is a critical decision for any woodworking or metalworking operation. An efficient circular saw grinding machine not only extends the lifespan of your blades but also ensures consistent, high-quality cuts, reduces downtime, and optimizes your overall workflow. However, with a wide range of options available on the market, it’s essential to focus on the features that truly matter. Below, we explore the top 7 features to look for in a circular saw grinding machine, providing a comprehensive guide for professionals seeking reliability, precision, and long-term value.

1. Precision and Consistency of Grinding

The primary purpose of a circular saw grinding machine is to restore blades to their optimal cutting condition. This requires a machine that delivers exceptional precision and repeatability. Look for models that offer:

- Adjustable grinding angles for both the top and face of the teeth, allowing you to match the original geometry of the blade.

- Fine-tuning capabilities for tooth pitch, depth, and clearance angles, ensuring each tooth is sharpened identically.

- Stable, vibration-dampening construction, which minimizes micro-movements during grinding and guarantees a uniform finish across the entire blade.

- A machine with these characteristics will consistently produce razor-sharp blades, reduce the risk of uneven wear, and minimize the need for frequent re-sharpening.

2. Versatility in Blade Compatibility

In a busy workshop, you're likely to encounter a variety of blade types and sizes. A top-tier grinding machine should accommodate:

A wide range of blade diameters, from small precision blades to large industrial saws, often spanning from 75 mm up to 850 mm or more.

Different tooth profiles, including flat, alternate top bevel, triple chip, and more.

Various blade thicknesses and tooth pitches, enabling the sharpening of both fine and coarse-toothed blades.

Versatility in blade compatibility not only enhances your shop's flexibility but also reduces the need for multiple specialized machines.

3. Automation and User-Friendly Operation

Modern grinding machines increasingly incorporate automation to boost productivity and reduce operator fatigue. Key features to consider include:

Programmable controls or CNC interfaces that allow you to store and recall grinding parameters for different blade types.

Automatic indexing, feeding, and clamping systems that streamline the sharpening process and minimize manual intervention.

Intuitive control panels with clear displays, making setup and monitoring straightforward even for less experienced operators.

Automation not only increases throughput but also ensures consistent results, regardless of operator skill level.

4. Efficient Cooling and Dust Management

Grinding generates significant heat and metal or carbide dust, both of which can affect blade quality and operator safety. The best grinding machines incorporate:

Wet grinding systems with integrated water tanks or coolant reservoirs, which keep the grinding wheel and blade cool, prevent overheating, and extend the life of both the blade and the wheel.

Effective dust extraction or enclosed cabins that contain debris and maintain a clean, safe workspace.

Easy-to-clean designs that facilitate routine maintenance and prevent buildup of residue.

These features are essential for maintaining a healthy work environment and ensuring the longevity of your equipment.

5. Robust Construction and Durability

A grinding machine is a significant investment, so durability is non-negotiable. Look for:

Heavy-duty steel or cast iron frames that provide stability and resist deformation over years of use.

High-quality components, such as precision-ground spindles and wear-resistant guides, which ensure smooth operation and long service life.

Waterproof or dustproof switches and controls, protecting sensitive electronics from workshop hazards.

A robustly built machine will withstand the rigors of daily operation and deliver reliable performance for years to come.

6. Adjustable Grinding Angles and Multi-Functionality

Different blades and cutting applications require different tooth geometries. A superior grinding machine should offer:

Adjustable grinding head angles, allowing for precise setting of both top and face bevels, often up to 45 degrees or more.

The ability to switch quickly between grinding the top, face, and even the sides of the teeth, maximizing versatility.

Support for additional operations such as chamfering, re-toothing, and slot grinding, enabling you to handle a wide range of blade maintenance tasks with a single machine.

Multi-functionality not only saves space but also increases your operational efficiency.

7. Safety Features and Ease of Maintenance

Operator safety and machine upkeep are crucial in any industrial setting. Prioritize machines that include:

Full or partial enclosures to protect users from sparks, debris, and accidental contact with moving parts.

Secure blade clamping systems that hold the blade firmly in place during grinding, preventing slippage and potential accidents.

Simple access points for routine maintenance, such as lubrication, wheel changes, and cleaning, reducing downtime and extending the machine's lifespan.

User-friendly maintenance features ensure your machine remains in optimal condition and minimize unexpected breakdowns.

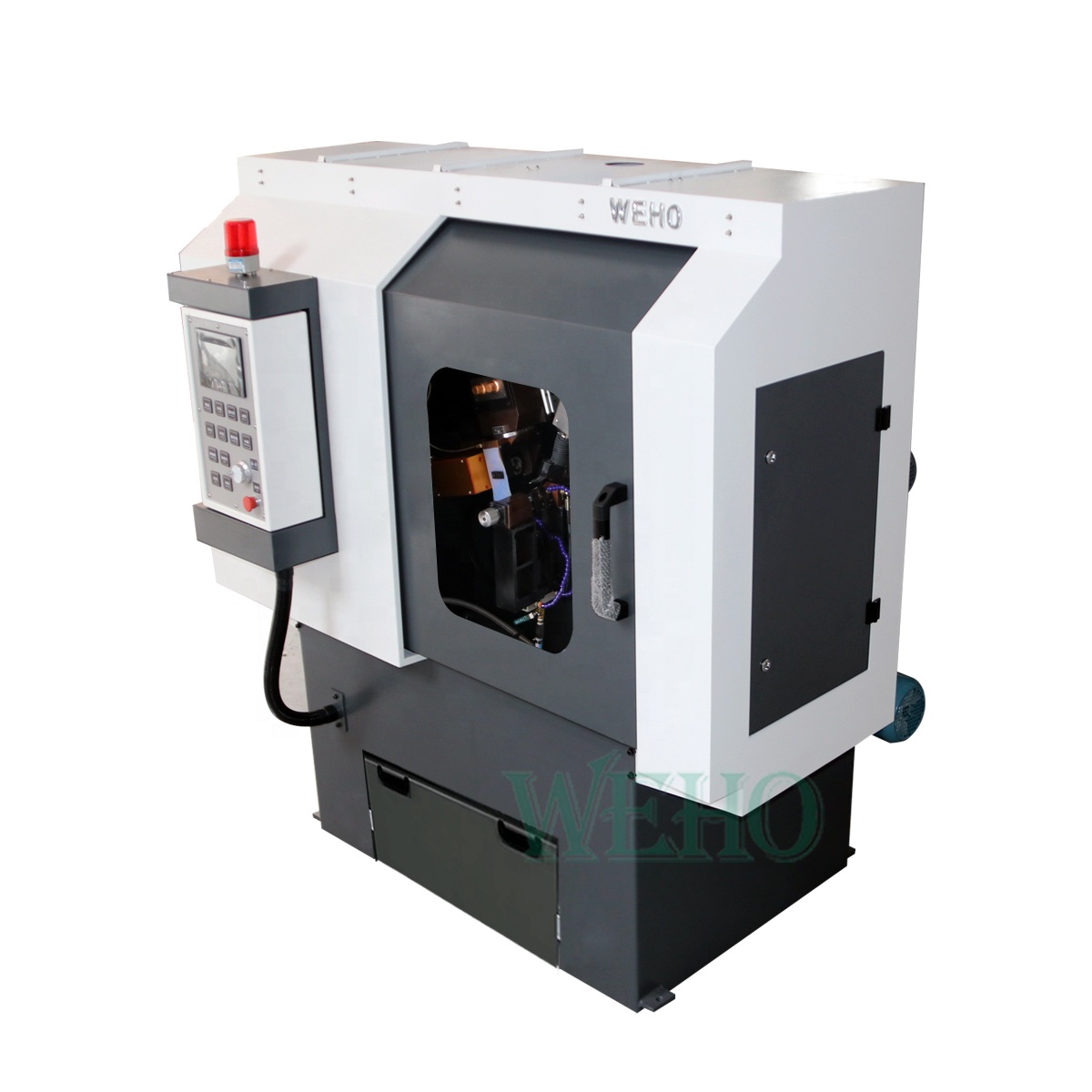

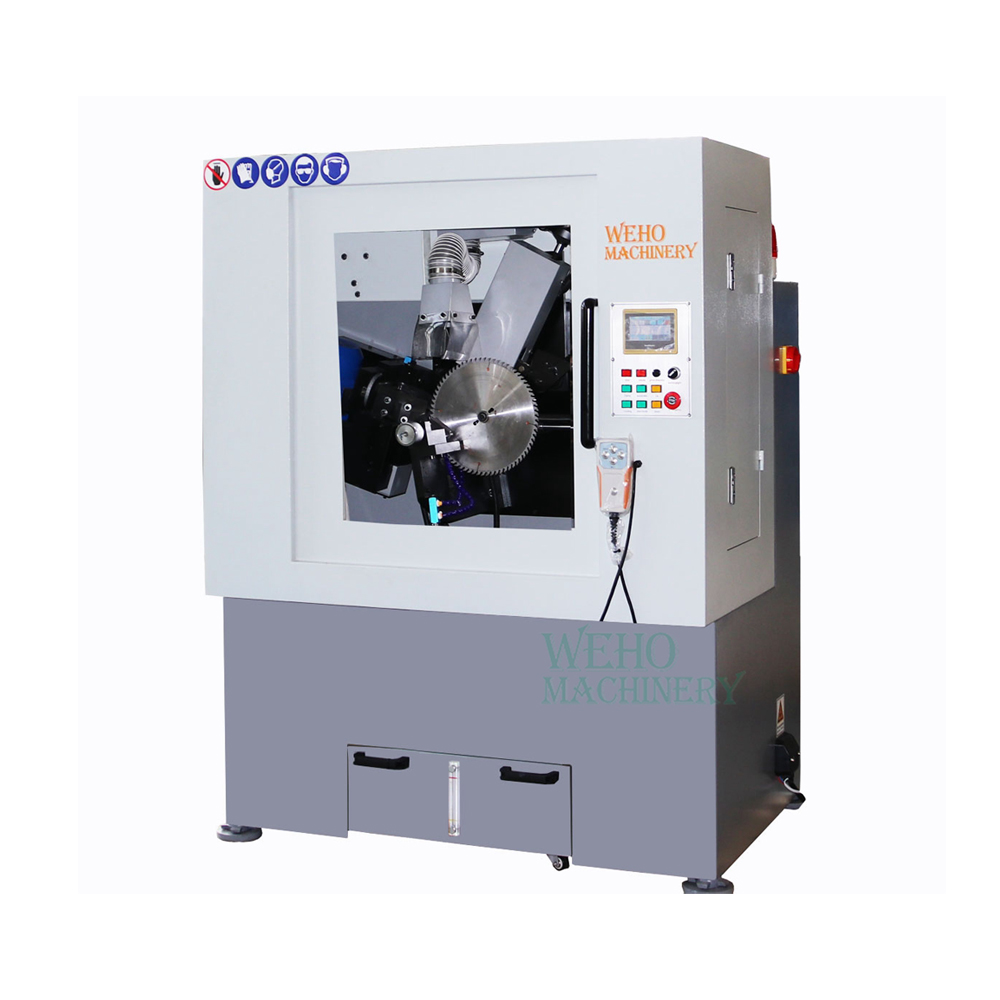

Why Choose WEHO for Your Circular Saw Grinding Machine Needs

As you evaluate your options for a circular saw grinding machine, it's essential to partner with a provider that understands the demands of modern workshops and delivers equipment that embodies all the features outlined above. WEHO specializes in advanced grinding solutions designed for precision, versatility, and long-term reliability. Our machines are engineered with robust construction, intuitive automation, comprehensive safety features, and flexible compatibility to meet the diverse needs of woodworking and metalworking professionals.

With WEHO, you benefit from:

State-of-the-art grinding technology that ensures razor-sharp, consistent results.

User-friendly controls and automation for effortless operation and high productivity.

Durable, low-maintenance designs that withstand intensive daily use.

Comprehensive support and customization options to fit your unique workflow.

Choosing WEHO means investing in a solution that grows with your business, enhances your operational efficiency, and delivers superior blade performance every time.

Conclusion

Selecting the right circular saw grinding machine is a decision that impacts every aspect of your production, from blade longevity to cut quality and overall shop efficiency.

A machine that excels in these areas will not only keep your blades in peak condition but also streamline your workflow, reduce costs, and support the long-term success of your operation. Prioritize these features in your search, and you'll be well-equipped to meet the evolving demands of your industry for years to come.